SHARE

Open Innovation in Energy, Gas and the Electricity sectors

If there is one sector where big challenges and opportunities can be found, that is the energy sector. Energy powers absolutely everything and is vital for homes, cities, industries, mobility, and the development of countries. For this reason, countries are increasingly worried about finding the most cost-efficient and environmentally-friendly way for energy supply. The answer might just be the introduction of open innovation in energy, gas, and the electricity sectors. You can visit our open innovation page where we show examples of engineering innovation solved by our community.

In summary, the biggest challenge is the transition to renewable energies (solar, wind, hydropower, tidal power, etc.) that eliminate the need for fossil or nuclear sources, which have a negative environmental impact that cannot be ignored anymore. It is evident that there’s been big technological progress in this field. The cost of a solar power plant has been reduced from 5,000 USD to 1,000 USD per installed kW. Thermal and coal facilities are also being dismantled like Hazelwood plant, which produced, up until 2017, 3% of greenhouse-effect gases in Australia.

However, solving the big energy challenge implies solving many other issues. Among them, we find the challenge around how to store variable energy, how to complement the different sources to maintain a 24h continuous supply or how to adapt to the extreme weather conditions of the new plants’ locations (the sea, deserts, etc.). A very interesting example of this challenge is solar power generation in the Atacama desert. This place, located North of Chile, has the highest radiation potential in the world. However, facilities must endure extreme radiation conditions, huge day/night temperature variation, heavy dust and water scarcity.

Here are open innovation in energy challenges on which ennomotive has worked or is working with some leading electricity and gas companies in Europe and America.

Open Innovation in Energy Challenges

Sediment control in regulating reservoirs from hydropower plants

Run-of-river hydroelectric power plants require a reservoir that regulates the flow upstream. In these reservoirs, and especially in some locations with a high amount of sand and clay, large volumes of sediments get accumulated and the regulation volume decreases. This situation has a direct impact on the plant’s ability to generate electricity, especially when the demand and the price are at their highest.

A leading company in hydropower generation in South America had a regulation reservoir with this sediment problem. During the summer, sediments take up 60% of the total capacity. Besides, the current cleaning solutions with dredging pumps were very costly and only solved the problem occasionally. For this reason, in September 2018, an innovation challenge was launched to find alternative ways to reduce the sediment accumulation in one of the company’s reservoirs. The goal was to find or develop new processes or technologies that kept at least 70% of useful capacity year-long.

The new solutions had to adapt to the reservoir’s shape, high-mountain extreme weather conditions, granulometry, and sediment cohesion, etc. 3 solutions were selected and awarded out of more than 80 solvers from all over the world. The winner was the Argentinian engineer Leonardo Guzmán, who came up with a sand-removal solution used in another industry.

Predictive maintenance in photovoltaic systems

Photovoltaic systems installed in houses of isolated villages in Mexico and Peru have a solar panel (Wp), a battery (100 Ah) and a controller. The lifespan of these batteries is drastically cut down when the load goes under 40%. Extending the lifespan of the battery without increasing the costs is key to provide good-quality service. For this reason, Fundación Acciona Microenergía and ennomotive jointly launched a social challenge in 2015.

The expected solution had to be both effective, easy to install, low-consumption and low-cost. In 6 weeks, they found 2 solutions that solved this challenge. The first one was designed by Andrés López-Aranguren, a Spanish engineer that had already worked in a similar cooperation project in Nicaragua. He designed a low-cost solution that collected data from domestic photovoltaic systems and could also be applied to this challenge.

The winning solution came from Michel Kuenemann, a French Electronics engineer that had developed an electronic card to monitor the charging status of aeromodelling plane batteries. His proposal was to adapt this solution to monitor the charging status of the photovoltaic system and automatically turn off the battery once reached the threshold. Besides, this solution had a cost under 20 USD.

Productivity in the maintenance of overhead distribution lines

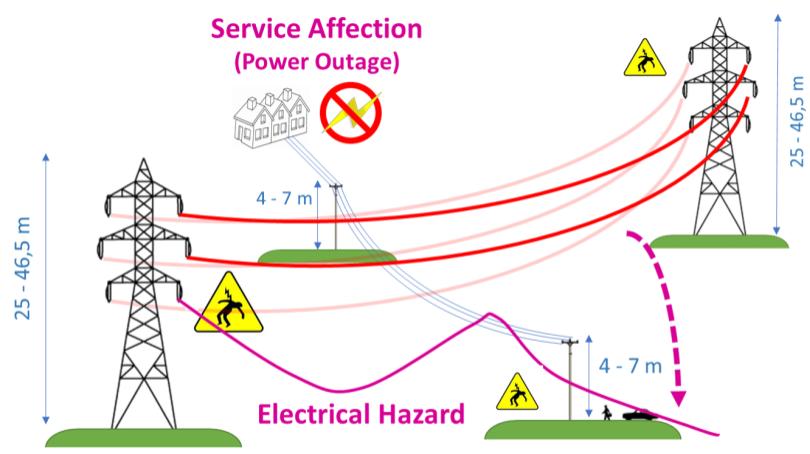

Apart from generation, both energy transportation and distribution are also fundamental to ensure good supply. To provide a good service, utilities perform preventive maintenance on the electric lines, nodes and transformation centers. When maintenance is performed on an overhead transmission line that crosses over an overhead distribution line, preventive activities are carried out to eliminate service cuts and to protect the technicians.

One solution would be to bury the distribution line underground, turning the original one off. Nevertheless, this solution is very costly and takes time to build. For this reason, Scottish Power launched a challenge in September 2017 to find alternative solutions to burying. These solutions had to be more efficient in time and cost, always ensuring the safety of the workers. In 3 months, many diverse solutions were found, from the design of automatic wiring-deployment systems and new tools to new processes to the optimization of the operation.

Finally, the winner was Gerdo Dalhousen, a Dutch civil engineer that proposed an easy-to-assemble-and-transport protection structure that complied with the technical and economic criteria of the challenge.

Scouting for gas metering stations

A gas distribution network has Regulating and Metering Station (RMS) with flow meters that work within given flow ranges. If the demand decreases below the flow meter tolerance in some areas, the RMS should be renovated. Building a new metering line in an existing RMS is very costly. For this reason, in 2017, ennomotive helped one of the main natural gas carriers in Europe with a challenge that looked for alternatives to adapt the current RMS stations so that they could continue to work with lower flows.

Regarding this challenge, the layout, plans of the RMS and the technical specs of the components of one line were published. Besides, the solutions had to comply with the EU norms and modify the current RMS stations at the lowest cost. Multiple practical solutions were found for this challenge, including, among others, ultrasonic devices, Coriolis technology, thermal meters, etc.

Optimize the investment for CNG supply in vehicles

Compared to gasoline and diesel, Compressed Natural Gas (CNG) is one of the most cost-efficient and clean alternatives to fuel power vehicles. However, to use it in vehicles, the NG must be compressed to be supplied at 200 bar with a reasonable investment. For this reason, Naturgy, a leading natural gas company in Spain and Latin America, launched in April 2019 a challenge to look for alternatives that substantially reduce both the initial investment and operational costs per facility. At present, we are in the first round of this challenge. There are 35.000 € in prizes and a percentage of the royalties generated after the implementation of the best solution.

Will you be the one who solves this challenge and turns the mobility upside down with gas-powered vehicles? If you want to know more about open innovation in energy, gas, or the electricity sectors, read the information here or contact us.