SHARE

Most Innovative Project 2018: PEMF and multi-wire method

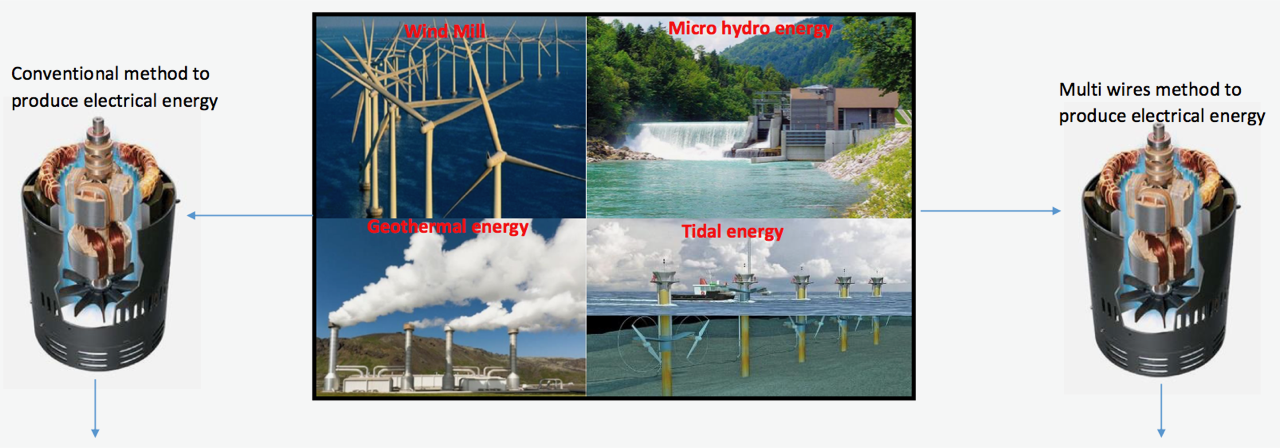

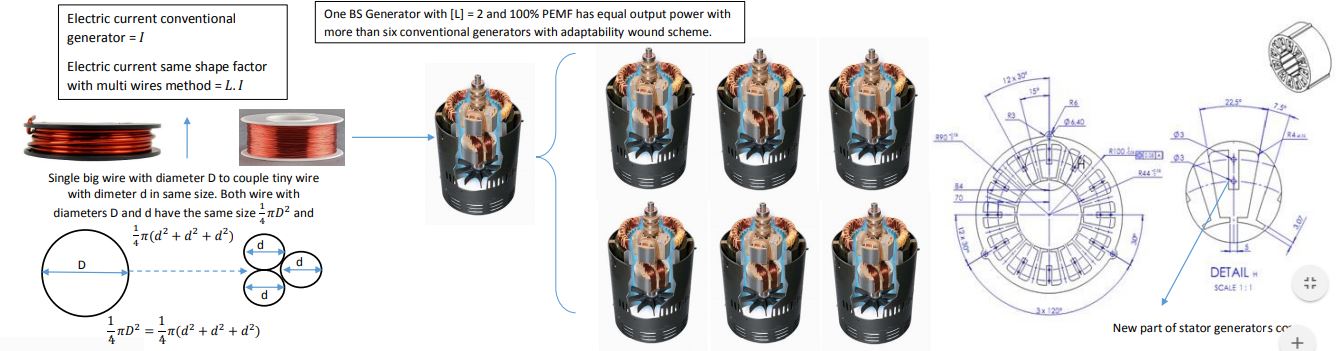

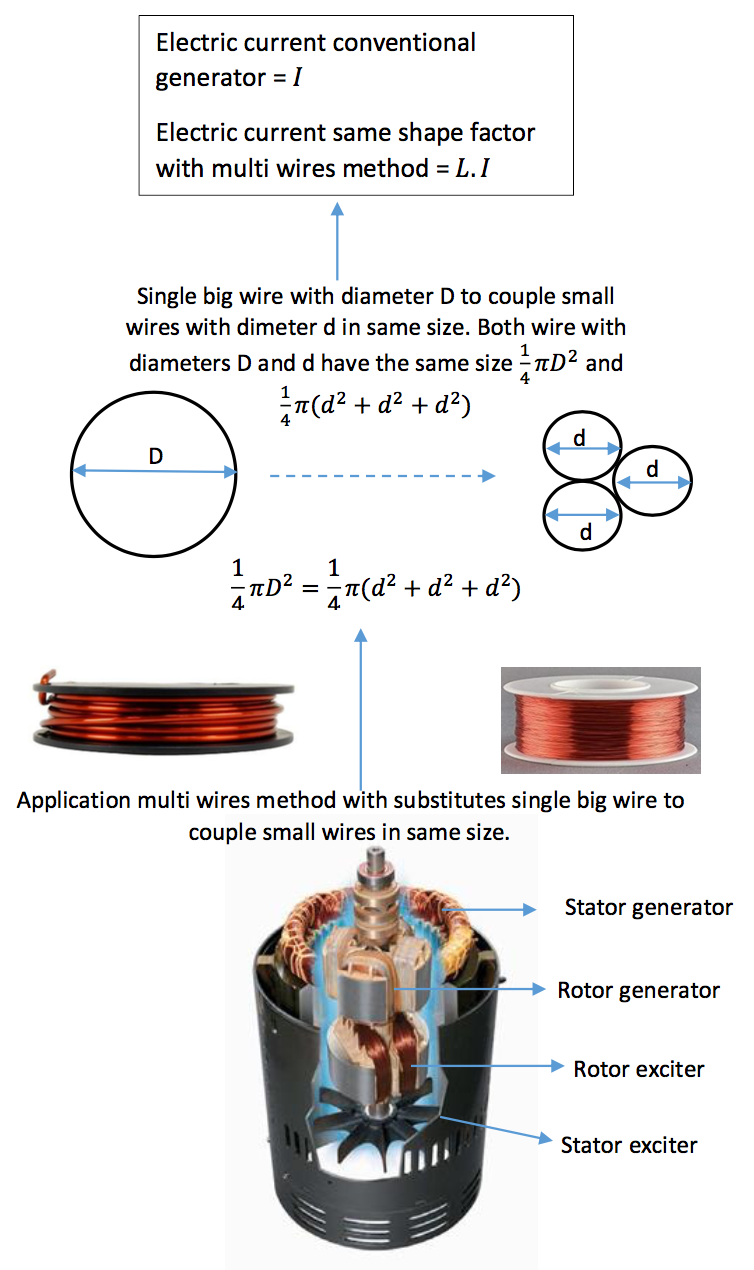

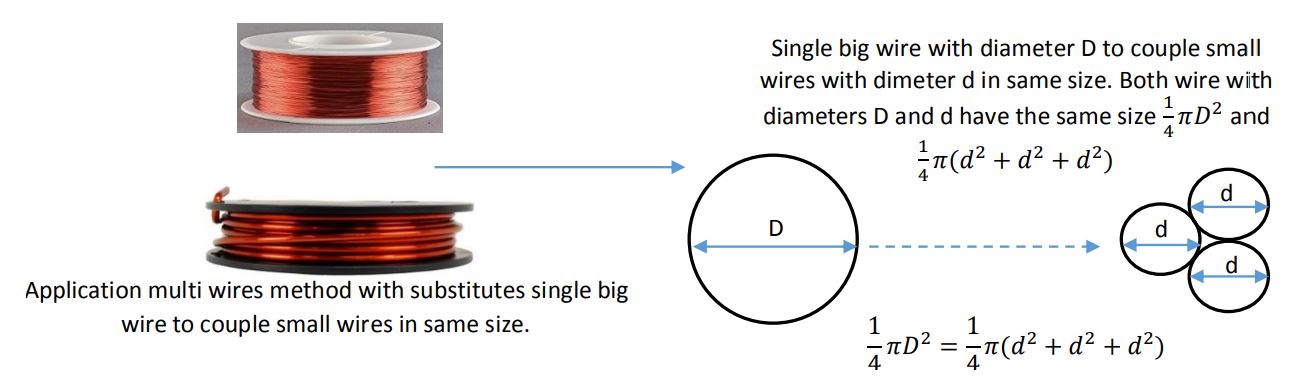

This project describes an innovation based on a multi-wires method that increases the electric current by reducing the obstruction of electrons in an electric generator or electric motor.

It is one of the projects ennomotive has received to compete in the ‘Most Innovative Project 2018‘ contest.

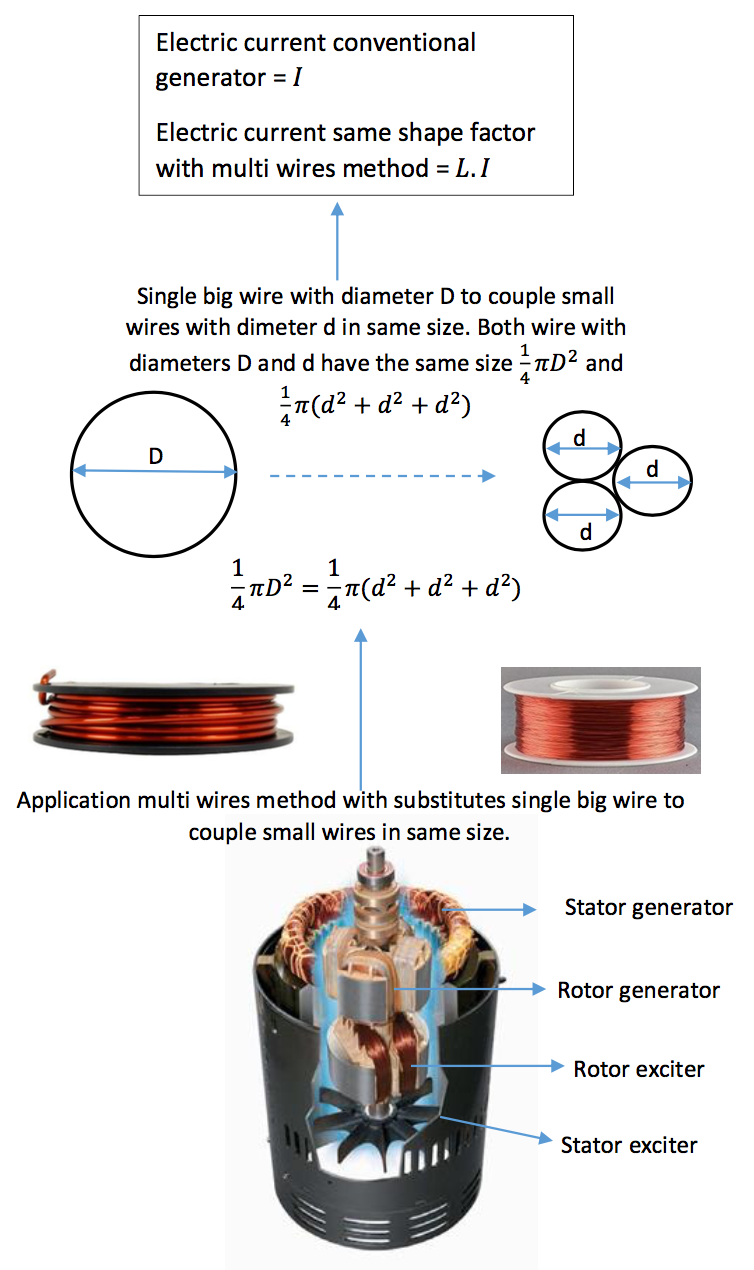

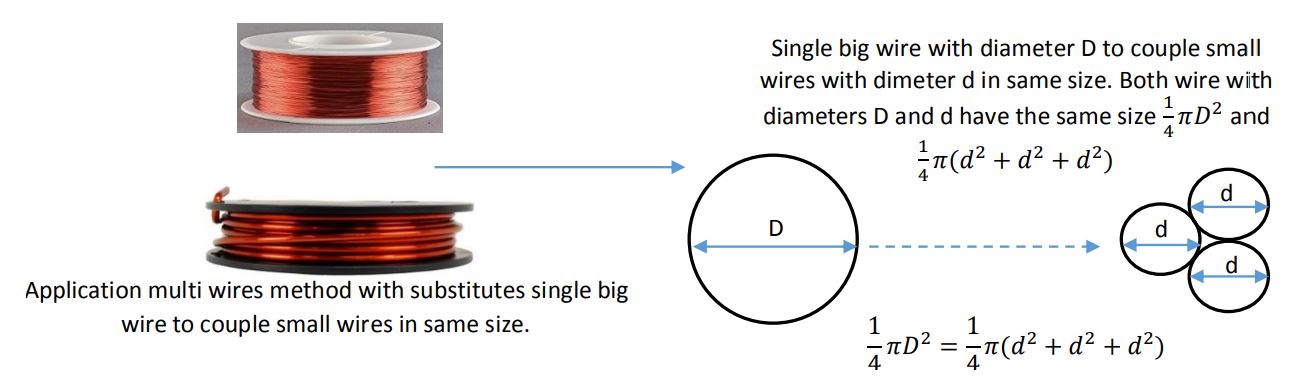

Inside the electric generator and electric motor, there is an obstruction in the electric current during the transformation of energy. This obstruction occurred because of the accumulation of too many electrons flowing on the external part of the wire, a phenomenon called skin-effect. However, it is possible to increase the flow area through an innovative multi-wire method, which will reduce the obstruction of electrons and the heat. This way, the electric current produced in a generator and electric motor will increase, thanks to an improvement in the transformation of energy.

The electrons flow and the potential difference or voltage is the cause-effect of the electro-motion force in the electromagnetic induction in a generator, sensor, detector, antenna, and Solar cell. If the potential reactivity of the electro-motion force is increased, it is also possible to increase that cause-effect conjunction. The main idea behind the PEMF method is to increase the potential reactivity and thus increase the potential difference in electromagnetic induction. If this method is applied to new innovations in the most important parts of a generator, electric motor, sensor, detector, antenna, and solar cell, there will be a better energy transformation.

This greener energy generating method can be easily implemented everywhere and it will considerably reduce the production and operation cost. The PEMF method is compatible and applicable to existing conventional technology, reliable, profitable and to the manufacturing industry and service providers and also helps to take care of the environment.

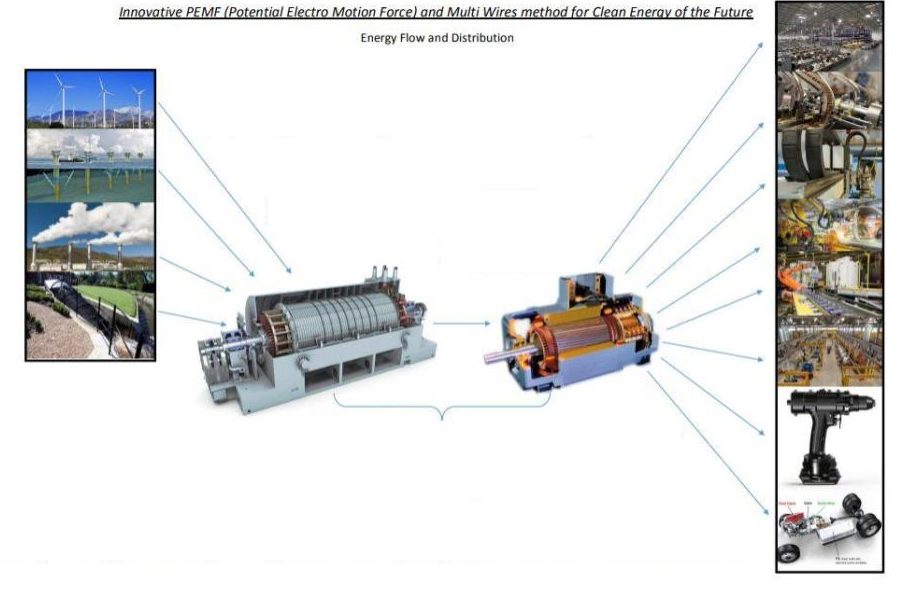

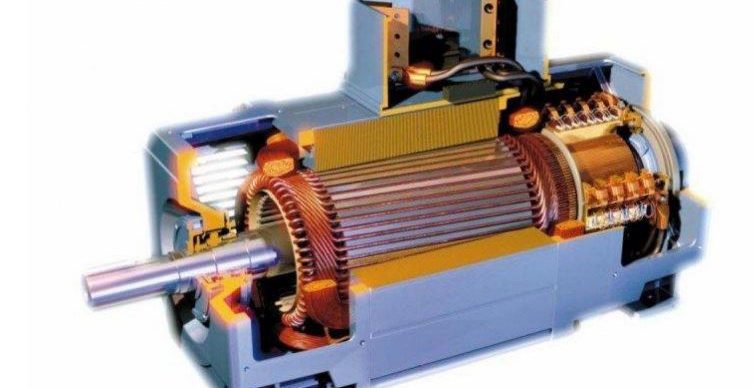

All kinds of technologies need energy and, to improve our quality of life, humans overuse energy sources to power these technologies almost to the point of exertion. Both motors and generators act as gates in the transformation of energy resources to power technology.

However, an electricity generator converts more than 80% of mechanical energy to electrical energy, and an electric motor uses more than 80% of electrical energy to generate movement. By increasing the technology of the gate, the production of energy and the energy efficiency will also increase and there will be a reduction in energy cost. This can be achieved with the PEMF and multi-wire method.

All kinds of technologies need energy and, to improve our quality of life, humans overuse energy sources to power these technologies almost to the point of exertion. Both motors and generators act as gates in the transformation of energy resources to power technology.

However, an electricity generator converts more than 80% of mechanical energy to electrical energy, and an electric motor uses more than 80% of electrical energy to generate movement. By increasing the technology of the gate, the production of energy and the energy efficiency will also increase and there will be a reduction in energy cost. This can be achieved with the PEMF and multi-wire method.

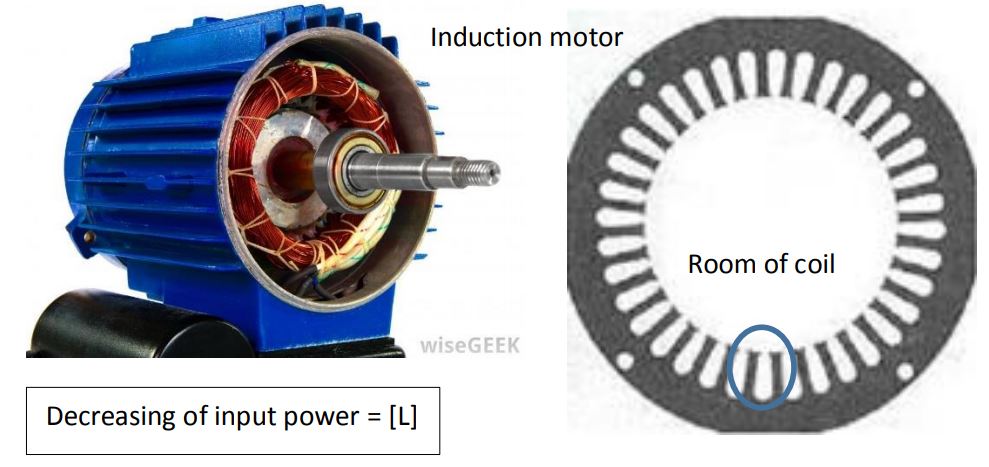

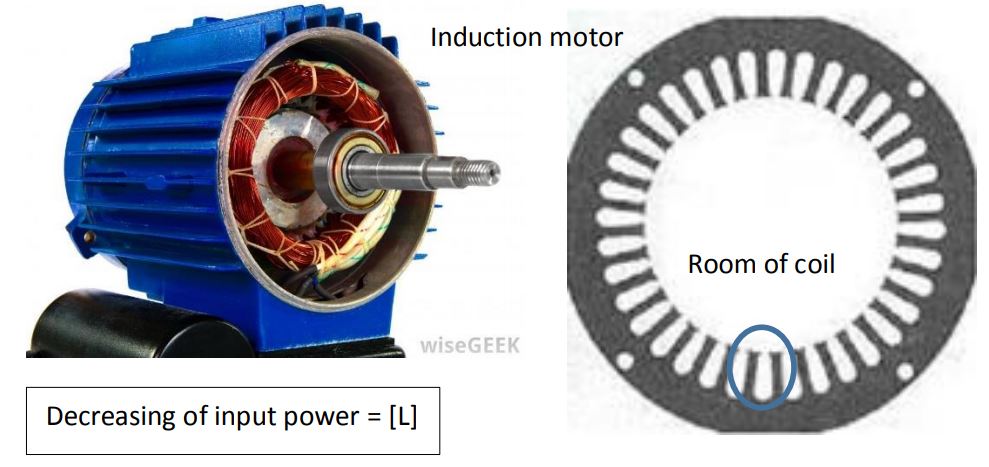

In order to produce the same torque and output power with a multi-wire electric motor than with a conventional motor, the power input of the electric motor can be reduced.

For examples substitute single 0.4 mm diameter wire to four 0.2 mm diameter wire have Factor increasing = 2 that make reducing 50% of input power and decrease operational cost.

In order to produce the same torque and output power with a multi-wire electric motor than with a conventional motor, the power input of the electric motor can be reduced.

For examples substitute single 0.4 mm diameter wire to four 0.2 mm diameter wire have Factor increasing = 2 that make reducing 50% of input power and decrease operational cost.

For example if one big email wire 0.4 mm of diameter can substitute to 4 of 0.2 mm wire but in this option is use 2 of 0.2 mm wire and adds 4 2⁄ or (2) count of coil of stator than count before. Increasing count of coil give chance to decrease electric current of input power be 2 4⁄ and [L] factor of increasing discretion of electric flow of two 0.2 mm wire than single 0.4 mm wire = 1 so with same of torque.

With substitute single 0.4 mm of wire to two 0.2 mm wire give more room coil in stator ± 50% so adds count of coil or 4/2 (2) two times count of the coil than count before to reach equal torque. This option will decrease the operational cost by 50% and make costumer more interested. Decreasing the input power of the electric current must change electric motor controller or driver to driver or controller that has match current.

For example if one big email wire 0.4 mm of diameter can substitute to 4 of 0.2 mm wire but in this option is use 2 of 0.2 mm wire and adds 4 2⁄ or (2) count of coil of stator than count before. Increasing count of coil give chance to decrease electric current of input power be 2 4⁄ and [L] factor of increasing discretion of electric flow of two 0.2 mm wire than single 0.4 mm wire = 1 so with same of torque.

With substitute single 0.4 mm of wire to two 0.2 mm wire give more room coil in stator ± 50% so adds count of coil or 4/2 (2) two times count of the coil than count before to reach equal torque. This option will decrease the operational cost by 50% and make costumer more interested. Decreasing the input power of the electric current must change electric motor controller or driver to driver or controller that has match current.

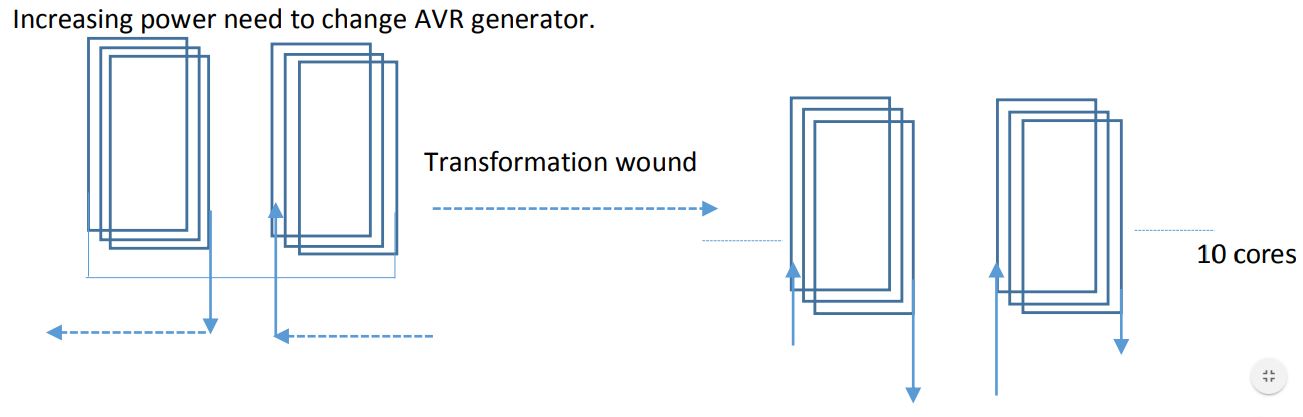

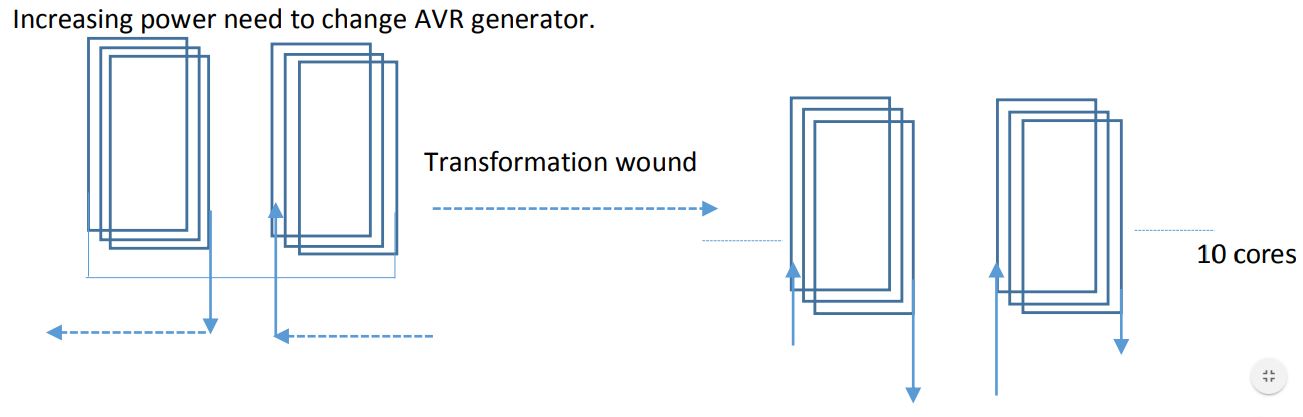

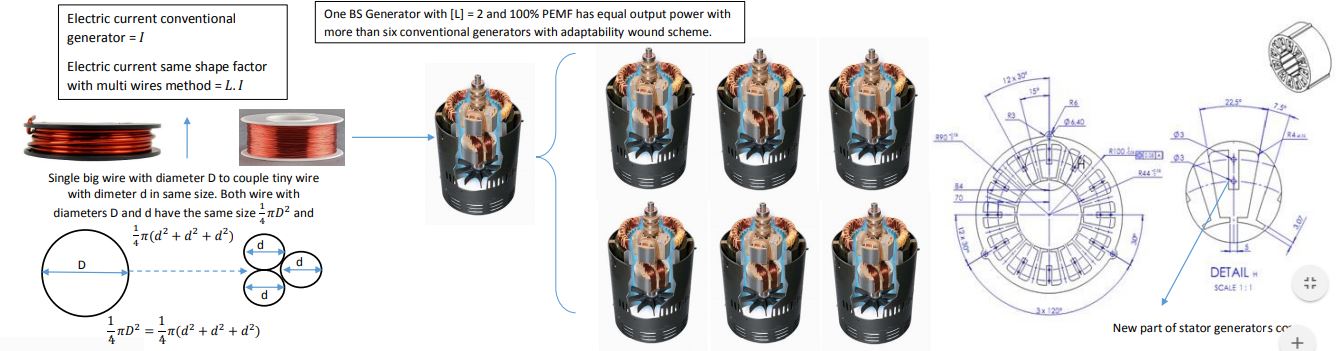

Transformation wound ten series cores to ten shunt cores in all cores stator generator to reach same voltage output and with application multi wires method and PEMF method in each core rotor exciter and stator generator make it generator equal power output with 10 conventional generators with same shape factor.

Transformation wound ten series cores to ten shunt cores in all cores stator generator to reach same voltage output and with application multi wires method and PEMF method in each core rotor exciter and stator generator make it generator equal power output with 10 conventional generators with same shape factor.

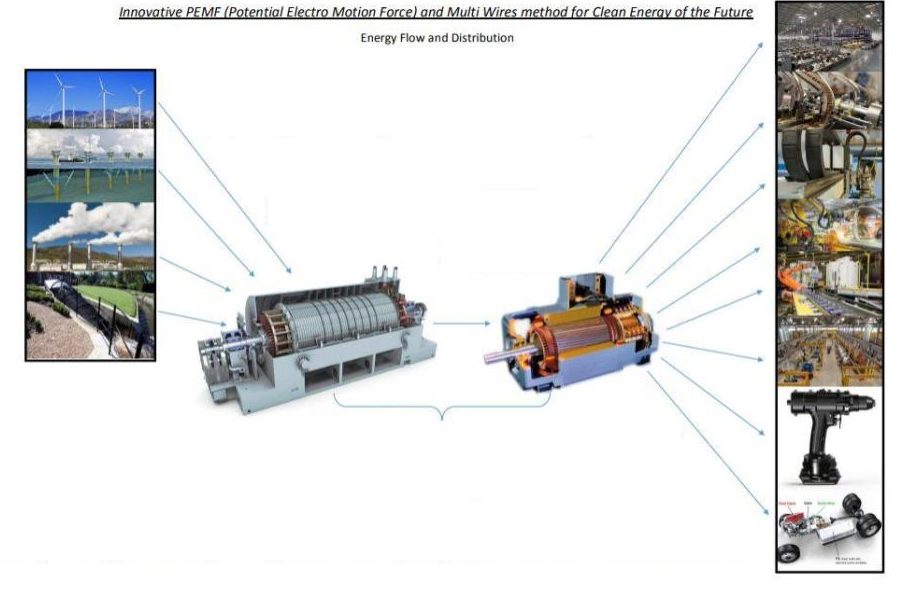

Innovative PEMF (Potential Electro Motion Force) and Multi-Wire method for Clean Energy of the Future

All kinds of technologies need energy and, to improve our quality of life, humans overuse energy sources to power these technologies almost to the point of exertion. Both motors and generators act as gates in the transformation of energy resources to power technology.

However, an electricity generator converts more than 80% of mechanical energy to electrical energy, and an electric motor uses more than 80% of electrical energy to generate movement. By increasing the technology of the gate, the production of energy and the energy efficiency will also increase and there will be a reduction in energy cost. This can be achieved with the PEMF and multi-wire method.

All kinds of technologies need energy and, to improve our quality of life, humans overuse energy sources to power these technologies almost to the point of exertion. Both motors and generators act as gates in the transformation of energy resources to power technology.

However, an electricity generator converts more than 80% of mechanical energy to electrical energy, and an electric motor uses more than 80% of electrical energy to generate movement. By increasing the technology of the gate, the production of energy and the energy efficiency will also increase and there will be a reduction in energy cost. This can be achieved with the PEMF and multi-wire method.

- The PEMF or multi-wire method increases the electric energy output of a generator if compared to a conventional generator without having to increase the scale, cost of production or input power.

- It will decrease the energy input consumption and the operation cost.

- It will maintain the availability of the energy source.

- It will increase the profit of electric power providers.

- The multi-wire method can increase the rotation or torque on all kinds of electric motors without increasing the scale and input power.

- An electric motor with the multi-wire method can increase the velocity of rotation and torque with same input power, therefore, to achieve the same rotation, the power input can be reduced to become more efficient and greener.

- This method can decrease the production cost, the operational cost of the electric motor, the heat, the dimension and weight of the battery (the count of cells of the battery), or it can increase the life of the battery.

- It is compatible with other applications and it has more advantages.

- This motor will increase quality production of the industry.

- It will decrease the operations cost and increase the profit of the industry.

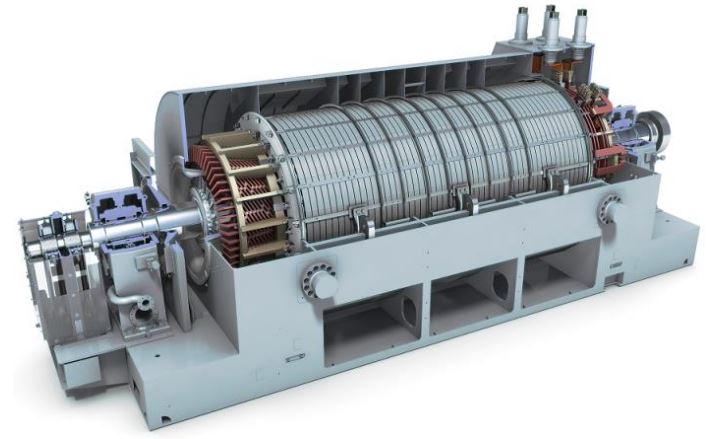

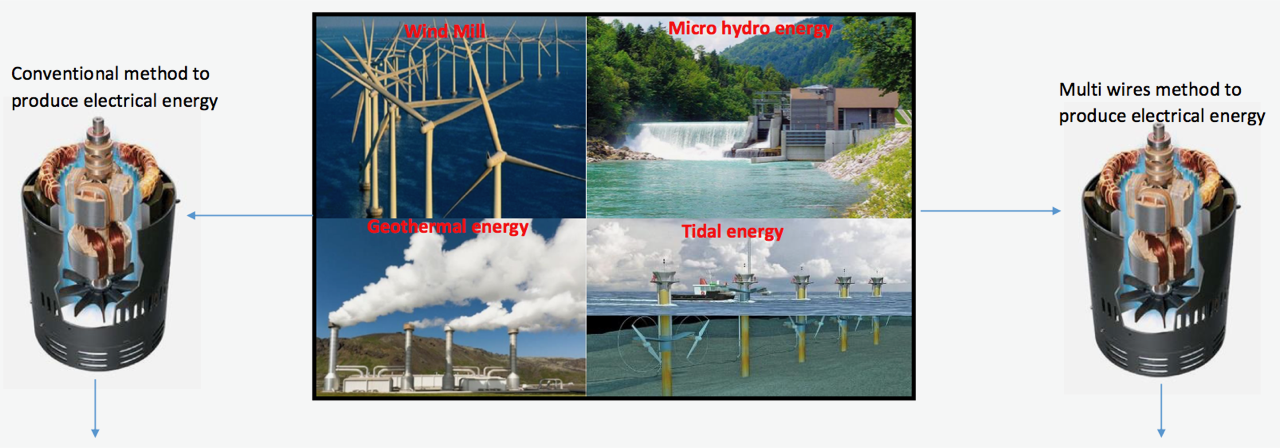

The multi-wire method brings innovation in the electromagnetic induction and in various options in generator applications

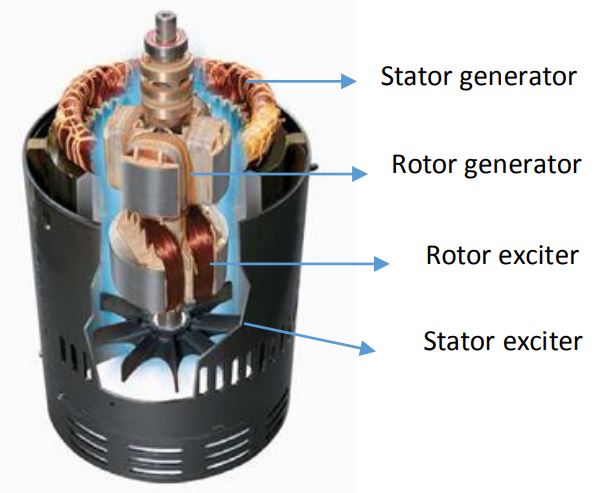

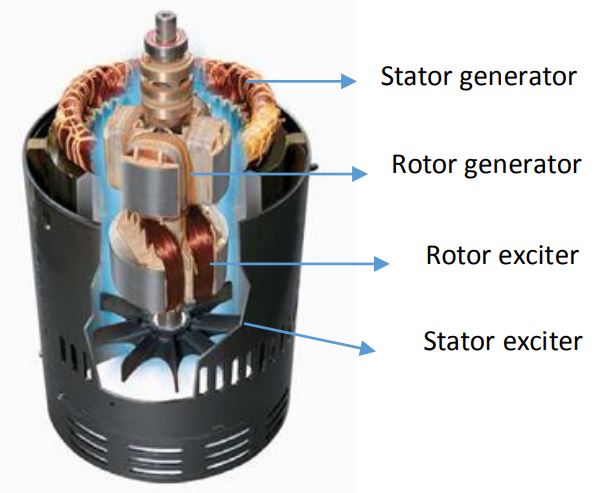

This method increases the electrical energy output of the generator without increasing its scale or cost of production. Since there is an increase in the production of power in the generator with the same shape factor and the input power is the same than a conventional generator, it is possible to decrease the size of the generator to produce the same level of energy as a conventional one, increasing its efficiency. One multi-wire generator with [L] = 2 has an equal output power with two conventional generators if we apply the multi-wire method to the stator generator. However, if we apply it to the exciters rotor and the stator generator with the adaptability wound scheme, that generator has a power equal to 4 generators or more. With the same wound scheme, the power increases if we use the multi-wire method just in the electric current. Therefore, if we apply the multi-wire method to the stator generator with [L] = 2, the electric current output will increase, without increasing voltage output. With [L] = 2 application multi wires method in rotor exciter, rotor generator and stator generator The stator exciter is usually in DC current, so the multi-wire method does not work. The rotation rotor makes the rotor exciter inducted by the stator exciter and the multi wires method with [L] =2, which will increase the electric current to the rotor generator times 2 than the conventional method (100%). An increase in the electric current will increase the magnetic wave times 2 to induct stator generator. Without a change of voltage output and rotation rotor scheme of the stator, the wound has to change.Transformation wound scheme

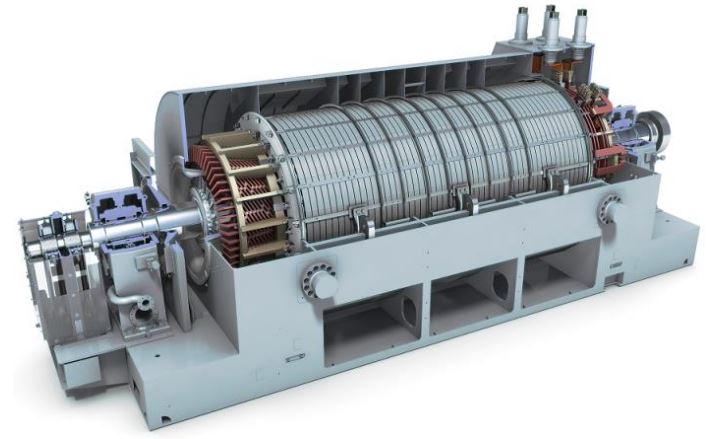

The multi-wire method generator increases the output power or reduces the generator'size

The conventional method to produce electric energy

- Low and Unstable output energy production.

- Relatively high-cost energy production, installation, and operation compared with its output of energy.

Multi-wire method for producing electric energy

- This method increases the electric energy output generator without increasing the scale, cost of production and input power in the same shape factor of the generator.

- The increase of the generator's power production with the same Shape factor and input power than a conventional generator means that a smaller generator can produce an equal power level and become more efficient.

- This new technology increases energy production, it is stable, compatible and has a low-cost production and application.

The multi-wire method in the electromagnetic induction and various advantages in the generator applications

A generator with the multi-wire method

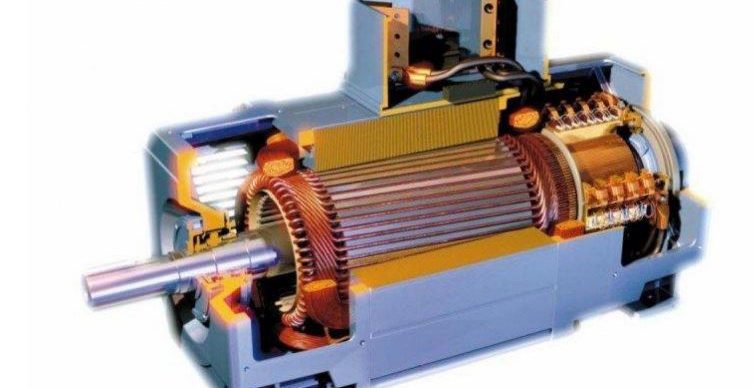

The multi-wire method generator increases the output power or reduces the electric motor's size

Conventional method electric rotating machine

- High input.

- Relatively high-cost energy consumption, installation, and operation if compared with the energy output.

The multi-wire method in an electric rotating machine

- It increases the multi-times velocity of rotation and torque with the same power input, which means that this power input can be reduced to achieve the same rotation of a conventional electric motor.

- It decreases the production cost, the operational cost of the electric motor, the heat and the weight of the motor and it increases the life of the battery.

- It is compatible with other applications and it has more advantages.

- This motor will increase quality production of the industry.

- It will decrease the operations cost and increase the profit of the industry.

The PEMF method and multi-wire method in electromagnetic induction to decrease the input power in induction motor applications

For electric motor (All kinds of electric motors)

The multi-wire method can increase rotation or torque on all kinds of electric motors without increasing the scale and input power. An electric motor with the multi-wire method can increase its multi-times velocity of rotation and torque with the same input power or decrease the input power to reach the same rotation of a conventional electric motor, which makes it greener and more efficient. This method can reduce the production cost, the operational cost of an electric motor and the heat. In order to produce the same torque and output power with a multi-wire electric motor than with a conventional motor, the power input of the electric motor can be reduced.

For examples substitute single 0.4 mm diameter wire to four 0.2 mm diameter wire have Factor increasing = 2 that make reducing 50% of input power and decrease operational cost.

In order to produce the same torque and output power with a multi-wire electric motor than with a conventional motor, the power input of the electric motor can be reduced.

For examples substitute single 0.4 mm diameter wire to four 0.2 mm diameter wire have Factor increasing = 2 that make reducing 50% of input power and decrease operational cost.

Explanation of how the multi-wire method in an induction motor can decrease the operation cost

For example if one big email wire 0.4 mm of diameter can substitute to 4 of 0.2 mm wire but in this option is use 2 of 0.2 mm wire and adds 4 2⁄ or (2) count of coil of stator than count before. Increasing count of coil give chance to decrease electric current of input power be 2 4⁄ and [L] factor of increasing discretion of electric flow of two 0.2 mm wire than single 0.4 mm wire = 1 so with same of torque.

With substitute single 0.4 mm of wire to two 0.2 mm wire give more room coil in stator ± 50% so adds count of coil or 4/2 (2) two times count of the coil than count before to reach equal torque. This option will decrease the operational cost by 50% and make costumer more interested. Decreasing the input power of the electric current must change electric motor controller or driver to driver or controller that has match current.

For example if one big email wire 0.4 mm of diameter can substitute to 4 of 0.2 mm wire but in this option is use 2 of 0.2 mm wire and adds 4 2⁄ or (2) count of coil of stator than count before. Increasing count of coil give chance to decrease electric current of input power be 2 4⁄ and [L] factor of increasing discretion of electric flow of two 0.2 mm wire than single 0.4 mm wire = 1 so with same of torque.

With substitute single 0.4 mm of wire to two 0.2 mm wire give more room coil in stator ± 50% so adds count of coil or 4/2 (2) two times count of the coil than count before to reach equal torque. This option will decrease the operational cost by 50% and make costumer more interested. Decreasing the input power of the electric current must change electric motor controller or driver to driver or controller that has match current.

The generator with PEMF (Potential Electro Motion Force) method

This method increases the electrical energy output of a generator even more than the multi-wire generator without increasing the scale, cost of production and input power. Besides, it has the same shape factor, an additional NdFeB magnet, and an adaptable design core stator and generator. This PEMF method increases the power production of a conventional generator. It can also reduce the scale of the generator in order to equal the power level and be more effective. Transformation wound ten series cores to ten shunt cores in all cores stator generator to reach same voltage output and with application multi wires method and PEMF method in each core rotor exciter and stator generator make it generator equal power output with 10 conventional generators with same shape factor.

Transformation wound ten series cores to ten shunt cores in all cores stator generator to reach same voltage output and with application multi wires method and PEMF method in each core rotor exciter and stator generator make it generator equal power output with 10 conventional generators with same shape factor.

The multi-wire method and 100% PEMF

Stator exciter usually in DC current, induct rotor exciter and does not inducted from another induction so make multi wires method and PEMF method do not work. Rotation rotor make rotor exciter inducted by stator exciter and with multi wires method with [L] =2 and 100% PEMF will increase electric power to rotor generator 5 times than conventional method. Increasing of electric power will increasing magnetic wave 5 times to induct stator generator.

Explanation multi wires and PEMF method in generator

From experiment 25% PEMF increase voltage ± 15% so 100% PEMF will increase 60% voltage and increasing ± 512% power just in exciter that All electric power will induct stator generator from rotor generator. With same [L] and level PEMF will increase 512% electric energy than conventional generator so totally increasing Is ± 1000% (ten times) that equal with 10 generators with same shape factor. Written by: Ridho Fermana Kusuma Did you like this project? Hit the Like button on this page and help Ridho become the winner of our contest ‘Most Innovative Project 2018‘.