SHARE

Mechanical Concrete: The Power of Sustainable Confinement

Samuel Bonasso is a Civil Structural Engineer from the U.S. who is also the President of Reinforced Aggregates Company. He shared with us some insights on a new sustainable technology, Mechanical Concrete. Read on.

Mechanical Concrete is a confined aggregate concrete—a geosynthetic product. A thin-walled cylinder provides lateral confinement for any type of stone aggregates. Lateral confinement improves the structural performance of all aggregate materials. Removing the sidewalls from a waste auto tire creates an industrial-strength, low-cost tire-derived-geosynthetic cylinder; and it reuses one of society’s most important and high-quality industrial products.

This approach to confining aggregates offers a major, new opportunity to rebuild and maintain rural transportation and civil infrastructure with general labor, light equipment, and indigenous materials. It uses geo-cylindrical confinement and it quantifies the contribution of cylindrical confinement to improving soil load supporting capacity.

Techniques for improving soil load-supporting capacity depend on how soil is viewed as a material. When soils are viewed as a collection of particles and internal friction or cohesion is the measure of their capacity to support external loads, the load improvement technique exhibits behavior and requires an explanation of a certain type. This explanation is not usually quantified by a specific increase in the soil load-supporting capacity but is generally defined by the achievement of an optimum level of compaction. Soils viewed as purely compressive materials similar to fluids, i.e. a partial or semi-fluid; spawn different load improvement techniques and explanations that can be directly measured.

Cylindrical confinement of granular soils produces a material change of state from a semi-liquid to a semi-solid, e.g. from water to ice. Such confinement generated changes of state deliver a significant and quantifiable improved external load carrying capacity, lab proven up to 200 psi.

[gallery columns="2" ids="21924,21926"]

The technology has been tested in the large structures laboratory of the Civil and Environmental Engineering of West Virginia University in two different cylindrical material confinement embodiments; cylinders made by removing both sidewalls from a waste tire, i.e., tire-derived-geo-cylinders, TDGC, and steel.

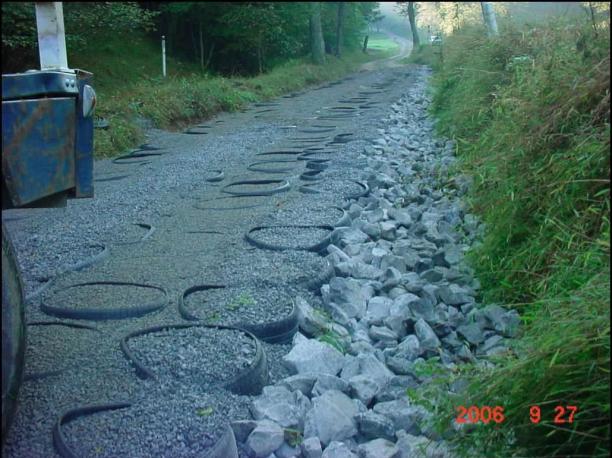

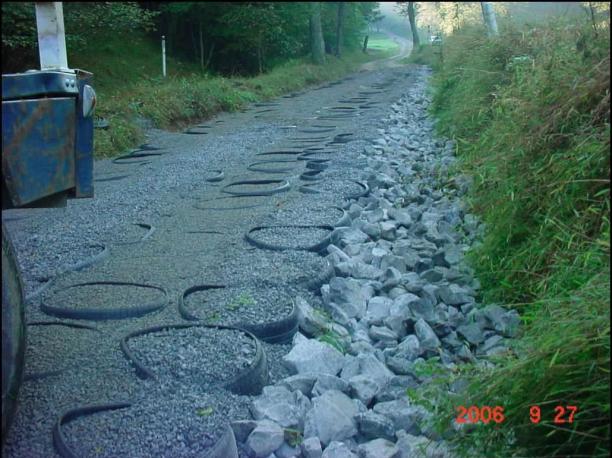

Utilizing TDGC, this embodiment has been used as a road base on public roads and industrial mining haul roads on projects in four of the United States; Arizona, California, West Virginia, and Ohio. Mechanical Concrete with TDGC has been approved for use by the West Virginia DOT Division of Highways. It has also been used as the facing for an MSE parking lot retaining wall and to repair roadside washouts.

Rural Road Reconstruction

Rural Road Reconstruction

Mon River Coal Loading Dock Access Road

Mon River Coal Loading Dock Access Road

US Mexican Border Road near Yuma Arizona, on fine Sand

US Mexican Border Road near Yuma Arizona, on fine Sand

Confined aggregate concrete can function in a variety of applications. As a road-base, it creates a mechanically stabilized free-draining base. Its Applications have been lab-tested and field-proven. For example, it can function as highway bases and shoulders, earth retaining walls, bridge abutments, & slope and channel erosion protection. It has been researched, developed, and demonstrated since 2005. It’s a strong and economical method for improving the structural performance of crushed stone aggregates and other man-made and natural aggregates. It’s simple to understand and easy to use.

Mechanical Concrete: the Projects

Rural Road Reconstruction

Rural Road Reconstruction  Mon River Coal Loading Dock Access Road

Mon River Coal Loading Dock Access Road US Mexican Border Road near Yuma Arizona, on fine Sand

US Mexican Border Road near Yuma Arizona, on fine SandConfined aggregate concrete can function in a variety of applications. As a road-base, it creates a mechanically stabilized free-draining base. Its Applications have been lab-tested and field-proven. For example, it can function as highway bases and shoulders, earth retaining walls, bridge abutments, & slope and channel erosion protection. It has been researched, developed, and demonstrated since 2005. It’s a strong and economical method for improving the structural performance of crushed stone aggregates and other man-made and natural aggregates. It’s simple to understand and easy to use.

Confinement

Confinement is one of nature’s main ways of holding aggregate and soil particles together; plus, gravity, friction, and adhesion. Geosynthetic fabric technologies work by improving friction. This technology is the first economical, industrial-strength method of confining aggregates. New-tire design factors make a tire-derived-geo-cylinder, TDGC, as much as 5x stronger than most designs require—that’s virtually indestructible in civil engineering, mining, heavy construction, and agricultural applications. Reusing waste-tire-cylinders is green, strong, and economical; costs 30% to 50% less than other confinement technologies. A single TDGC can cost as little as $2 in truck-load lots of 3000 TDGC. It has regularly improved maintenance costs on rural unpaved roads by 75% and it creates a pothole-less asphalt surface. It has performed with zero cracking under concrete pavements for over 10 years with an ADT of 600 trucks per day. Worldwide, societies generate nearly 1.4 billion waste automotive tires per year (300 million from the USA). This confinement method was discovered by seeking better re-use for waste tires. Mechanical Concrete uses 12,000 TDGC per 12-foot wide lane mile. Confining stone aggregates in tier-derived-cylinders provides four-dimensional sustainably.- Technical Superiority: Easy to use and install; with consistent outcomes—every time, everywhere, without testing. 60 to 100% stronger than compacted crushed stone construction.

- Economic Viability: Available in all 50 states. Reduces all costs—initial; maintenance, & life cycle.

- Environmental Friendliness: Reuses a major societal waste. Uses less material, energy, water, and skilled labor.

- Societal Effectiveness: Uses unskilled labor, smaller equipment, preserves resources, improves productivity

Walls & Erosion Control APPS

Using TDGC as a crib retaining wall system; eliminates active soil pressure and cuts cost by half compared with gabions, cribs, or MSE concrete facings. Using it as a ditch lining, erosion control system, it dramatically reduces water velocity and absorbs water energy.Pothole Termination APP

Pothole and rut failures cost consumers $Billions annually. Water penetrates the surface—into the compacted base-stone binder causing it to lose friction & strength. Mechanical Concrete tire-derived-geo-cylinders, laid down “round-to-the-eye”, physically confines and holds AASHTO #57 base stone together. This process consistently creates a virtually indestructible, water-permeable base. It reduces or eliminates:- Potholes & Ruts

- Road Edge Collapse

- Soft Subgrade Failures

- Ditch & Channel Scour

- Active Soil Pressure