SHARE

The Future of Solar Energy: High Concentrated Photovoltaic (CPV) Cells

Written by Olivier Loidi

In August 2018, ennomotive launched a circular economy challenge to find ways to repurpose waste materials found in mine tailings. For 6 weeks, 74 engineers from 30 countries accepted the challenge and submitted different solutions. After a thorough evaluation, the solutions that best met the evaluation criteria were submitted by Cliff Edwards, from Canada, and Oliver Loidi, from France. ennomotive asked Olivier to write an article about a topic he likes and here are his views on the future of solar energy and the high concentrated photovoltaic.

Solar energy is key for curbing global warming, I truly believe that. As a matter of fact, ten years ago I was actively working in this field and most particularly in the high concentration photovoltaic field (CPV). Back then it was seen as a true competitor for standard PV panels, but years of aggressive price-dumping have seriously undermined its development. The short-term approach of 'low capital cost/low lifespan' of standard PV appears to be much more tempting than the wiser 'moderate initial cost/long lifespan' path, even with more than double the efficiency. Now that standard solar panels begin to compete favorably with coal and gas and CPV companies still struggling to survive, it could be easy to conclude that the match is already over. However, research is still going strong to reduce the capital cost gap and, if the threshold is reached, could pave the way to a massive comeback for CPV.

In this article, I will try to explain the pros and cons of the CPV technologies along with my personal views of what should be improved to make it successful.

What is High Concentration Photovoltaic?

The principle of CPV is to focus sunlight onto an extremely high-efficiency solar cell that would be otherwise too expensive to use directly. These exceptional robust solar cells, usually made for space or military applications, can handle a concentration ratio of a thousand or more and still be nearly three times more efficient than a traditional PV cell made of silicon (Si-Pv). This approach has its own drawbacks: it needs to be directly oriented toward the sun and equipped with concentrating optics.

Types of optics

- Transmissive:

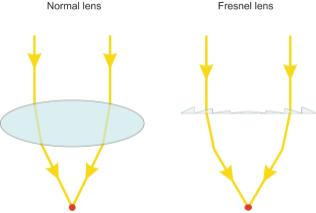

Magnifying lenses can be used, but the more elegant Fresnel lens design is the most often used.

- Reflective:

It involves concentrating sunlight with mirrors usually having a parabolic shape. Systems using one reflection do exist, but the most popular design is derived from the Cassegrain telescope, which allows less complex solar cell placement.

Advantages of CPV over normal solar panels

- Efficiency

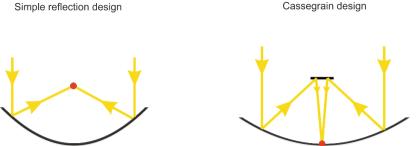

The best commercial silicon solar cells tops at 21% efficiency whereas multiple junctions cells used for CPV can reach 46% and are still improving, this gap in performance can be observed at the module level even with high optical losses for CPV.

- Very stable performance under high temperature

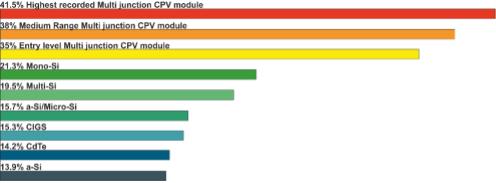

Silicon solar cells performance is very temperature-sensitive with a temperature coefficient of about -0.5% per °C, which means that for every degree above 25° (or 20°c depending on the manufacturer) it loses 0.5% of performance. This does not seem to be a lot but, in summer, it is not rare for it to reach 80°C (just like in a sun-exposed car) which would degrade the performance of a top-quality panel from 19% to only 14%! In contrast, CPV solar cells are made of materials with a very low-temperature coefficient of about -0.05%/°C with the best reaching -0.01%/°C which is nearly 10-50 times better than Silicon solar cells! This allows CPV cell to operate at very high temperature (100°c or more) without problems.

- Very stable performance under high temperature

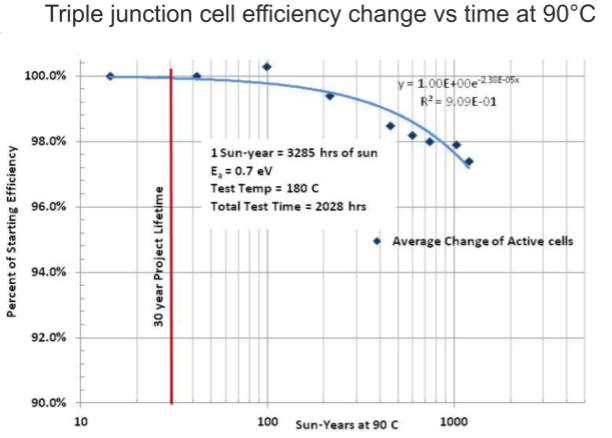

In all industrial systems, the active components are the most likely to fail or degrade and PV makes no exception. In traditional Si-Pv, the active components (solar cell) represents nearly 100% of the exposed surface in addition of electronic components (bypass diodes) so a chance of failure or degradation is a real issue. To make thing worse, the huge price competition prevents the use of very high-quality components which translate to poor long-term performance especially in very hot climates which also have major solar potential.

For instance, transparent plastics (EVA) used for encapsulation and gluing of the front glass are subjected to yellowing due to thermal cycling. Typical degradation rate are 0.5% per year in a temperate environment up to 3%/year in hot locations. CPV solar cells are derived from space and military applications and are virtually immune to thermal or radiation damage also concentration allows the use of premium electronics components as their numbers are also reduced. As the technology is relatively young, long term performance CPV does not exist per se but returns of similar technologies based on military or space applications seem to indicate a very stable performance even after 20 years of operation. All other exposed surfaces can be made of inorganic materials (glass, Aluminium) that do not degrade over time.

Source NREL

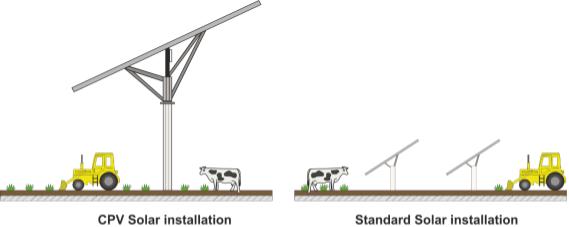

- Potential double usage of the land

Large trackers can be high enough to allow habitation or crops underneath it.

- Easily recyclable

CPV modules dismantling is easier because the constitutive elements are easily separable and composed mostly by inorganic material that can be fully recycled. On the contrary, SI-PV cells and frame are completely bonded to complex fluorinated plastics which requires advanced crushing and thermal treatment for partial recycling.

Why has CPV failed so far?

- Higher initial capital cost

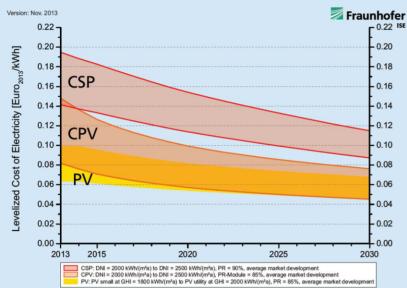

CPV may be more profitable in the long run but this advantage is not big enough to offset the much higher capital cost investment for the installation, which can go from 2.5 to 4 times higher than for traditional SI-PV technology.

Note CSP is electricity generation via solar thermal concentration

- Higher maintenance need

High precision tracking of the sun (up to 0.1° angular precision) needs constant attention from dedicated personnel. Also, the washing of the panels can be harder due to the height of the trackers.

- Clouds degrade performance

CPV can only work with direct sunlight, therefore it cannot operate all the time. CPV is usually aimed to be installed in a sunny location with over 80% of clear days per year. As a reference, CPV can only work if sharp shadows are present, which is the sign that sunlight comes mainly from one direction.

CPV works under small clouds, but not big ones. (source Wikipedia)

- Low land occupation density

To avoid shadowing effects in the morning or evening, trackers must be placed some meters apart. The resulting land occupation reaches only about 50%, that is only partially compensated by the 25% sun energy offered by tracking. In consequence, CPV is viable on low-cost land or if only one tracker is to be installed.

- Technology is still young

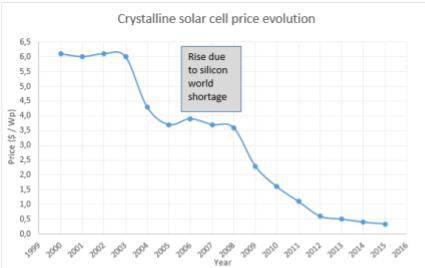

Although it is maturing quite fast, CPV suffered from a lack of dedicated supply chain, which forced every company to develop and produce themselves most of the components (trackers modules, etc..). Cells were too big at the beginning, which translated into high dissipation needs (bigger cells generate higher temperatures) and larger heavier modules which translated into additional operating costs. At the same time, the PV industry experienced a massive price drop of more than 80% coming from subsidized industries that could sell products with little to no profitability with the objective to gain share market.

Why CPV has the potential to succeed in the future

- CPV Cells are getting better, smaller, and cheaper

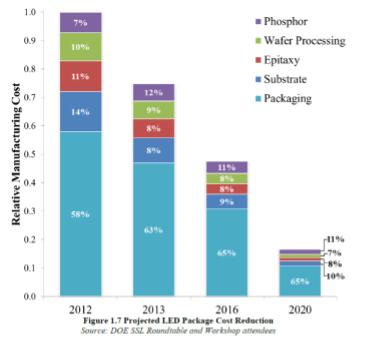

Multiple junction cells used in CPV benefit of the recent rise of the LED industry as the fabrication equipment is nearly the same. As many LED reactors can be retrofitted for CPV the price began to drop much faster than before. With the automated placement originally developed for LED, fabrication of extremely small cell designs is possible at high speed with very low fabrication errors. Standard sizes can be 25 times smaller than 10 years ago (4mm² vs 100) driving the module price down as small footprint cells dissipate heat more easily.

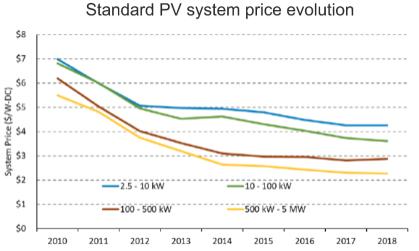

- SI-PV module price drop is stalling

Now that that the dust has settled after the PV trade war, Si-Pv modules prices have reached a plateau while CPV has still massive price drop potential.

Source NREL 2019

- Remaining available locations are more demanding

PV Installation in a temperate climate is a more and more competitive environment, so new solar-power growth must come from tougher locations. Places with the highest solar-energy potential, such as deserts, also happen to be the harshest. Standard PV panels components are having a tough time coping with the nigh/day thermal cycling, which results in far lower efficiencies compared to those installed in temperate climates.

What I think should be improved for CPV to be successful

As I said in the beginning, CPV has a special place in my heart and I never stopped thinking about new designs or possible improvements. Here are my thoughts on which points need attention for future CPV success:

- Reducing module weight is critical

Forget about pushing further the performance, module weight is by far a most important parameter when it comes to operating cost reduction simply because it allows larger tracker for the same precision and cost. More modules mean more revenues per global unit for the same maintenance, or even allows automated maintenance (cleaning) to be cost efficient, reducing further needed personnel. This is not a difficult task, as the weight has not been a parameter much optimized since the earlier generations. I have personally developed designs that weigh below 10kg/m² in comparison to the average 40-45 kg/m² of common CPV modules.

- Use of Fresnel lenses optic is a dead end

The idea behind them is incredibly elegant but it suffers from fatal flaws when it is used for precision solar concentration. Firstly, the design must be perfect to be truly effective: any compromise in the sharpness of the edges, such as the rounding that occurs with plastic molding, causes large degradation performance. Then, Fresnel lenses are very sensitive to pointing errors, the sun rays have an inherent +/-0.5° angular divergence which only leaves only a minuscule +/-0.1° room for tracking errors. Tracking with such precision is one of the major sources of maintenance cost for technologies using this kind of optics.

- Reflective optics should evolve from the classical “telescope design”

Reflective optics, despite their initial clunky look, does not suffer from the limitations of Fresnel lenses, they usually can cope with large tracking errors of more than +/- 1° allowing much lower maintenance costs. The only drawback is that the current designs based on the “Cassegrain telescope” are not easily mass produced with standard technologies which translate in very high fabrication costs Improving the fabrication cost can be done with the use of more “deformed” designs that get rid of the image formation to keep only the concentration capability, the possibilities are very large and I have created myself some design that can cut the production cost by 10 or more.

- Use of automated cleaning with very low water consumption

As explained earlier, CPV really shines in particularly harsh locations where water availability is usually very scarce. Adding a very economical cleaning system is essential, using existing building window-cleaning technologies rather than developing new ones could be the key.

Conclusion

CPV apparent demise may be just a setback as this technology still has the potential to outperform standard PV systems. Now that the dust has settled after times of frantic price dumping, CPV may play a great role as a durable tool for fighting global warming.

Tell us what you think the future of solar energy is and explore what ennomotive has to offer. Join our community of engineers