SHARE

Automation in Logistics: An Unstoppable and Useful Tech Trend

A few years ago, some visionaries said that robots would be everywhere, performing tasks for us such as cleaning, cooking, or driving. Although time has proven that those predictions were too optimistic, we can see that robots have actually helped us automatize many activities, like automation in logistics.

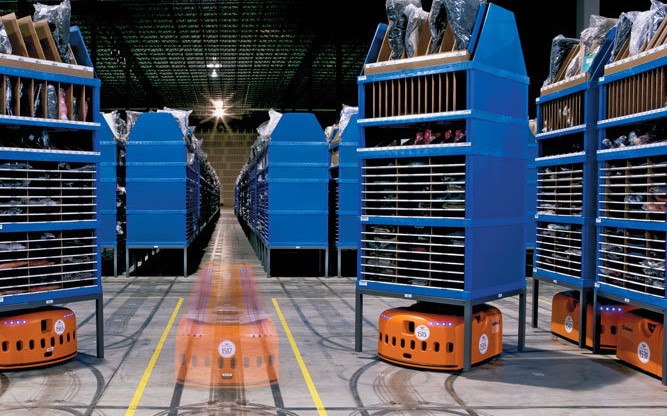

A great example is warehouse management. Nowadays we can see large traditional warehouses, in which big pallets of the same products are delivered, which are completely automated and need little human intervention.

However, the trend is changing and due to e-commerce, pallets are no longer made of a single material. E-shopping has forced many warehouses to produce small packages of different products, and automation is not so effective in this field. People are still working with no help and doing the hard job of walking continuously around the warehouse to pick the different desired products.

This job can be exhausting: workers may walk up to 15 miles (24 kilometers) every day, and therefore they usually quit sooner than later. Consequently, some new ideas about robots helping people have appeared in order to prevent workers from spending the whole day walking around a warehouse.

Secondly, another path is replacing people completely with robots. This path is still under development, but it is indeed in an advanced stage. To replace people we need piece picking robots. Two examples of companies working on automation in robotics are:

Secondly, another path is replacing people completely with robots. This path is still under development, but it is indeed in an advanced stage. To replace people we need piece picking robots. Two examples of companies working on automation in robotics are:

Automation in Logistics

First, one path that the industry is following is using robots that carry different materials back and forth. One example is Kiva Systems, which uses robots that move all around the warehouse while people stay in their workplace. Another instance is Fetch Robotics, where they use a robot that follows people around. A person takes stuff from the selves and puts it on the robot and once they have completed the package (can be up to 100kg), they deliver it somewhere else and go back to that person. Secondly, another path is replacing people completely with robots. This path is still under development, but it is indeed in an advanced stage. To replace people we need piece picking robots. Two examples of companies working on automation in robotics are:

Secondly, another path is replacing people completely with robots. This path is still under development, but it is indeed in an advanced stage. To replace people we need piece picking robots. Two examples of companies working on automation in robotics are:

- Again, Fetch Robotics, which uses the previously mentioned robot together with a piece-picking robot made up of an arm that boasts seven degrees of freedom with a gripper

- IAM Robotics, which uses a single robot that has an arm provided with a suction pad.