SHARE

Three new robots are changing the way cars are made

It is no secret that robotic technology has always played a significant role in the business of car-making. The first industrial robots were developed in the 1950s, although their implementation took place a decade later. Today, the industry is focused on developing new production methods that increase efficiency, which fuels a new wave of robotic innovation.

Many examples come to mind, but three have grabbed our attention the most:

1. Robot-to-Robot collaboration. GWM describes itself as China’s largest SUV and pickup manufacturer. Since 2011, its automotive plant in Tianjin has captured the attention of industry experts with its fast growth: it began working with a yearly production of 250,000 vehicles but its early figures for 2015 already bring that number all the way up to 800,000 units!

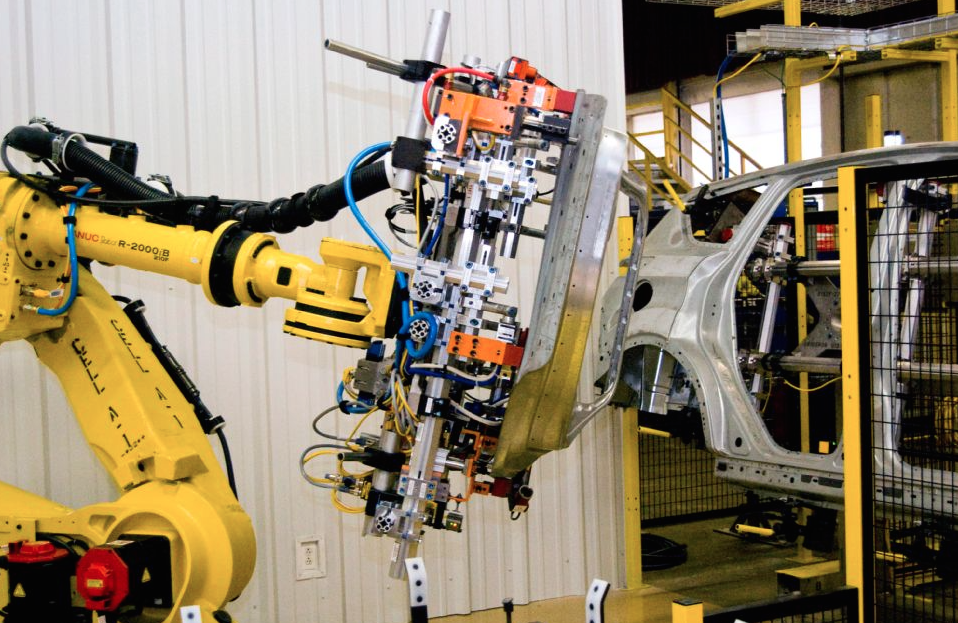

The key to this spectacular growth is Robot-to-Robot collaboration at the factory’s production line: some robots focus on handling and others take care of welding, which helps accelerate the car-making process.

2. Paint Robots. Industrial manufacturing has always relied on technology in order to accelerate the car painting process. Robots play a significant role because they quickly adapt to different design requirements while reducing the amount of paint that is wasted through their flowmeter technology.

The Robotic Industries Association has explained that this innovative solution is no longer reserved for an exclusive elite of industrial firms: “like all robotic technology, paint robots have become more viable for suppliers in the automotive and transportation industries”.

3. Robotic vision. Ford’s European factories began exploring this technology a few years ago, but its final breakthrough came in 2013, with the US-based production of the new Escape model. How does it work?

These robots incorporate what Motor Trend describes as “an array of lasers and cameras as eyes, which help them install parts on the vehicle bodies more precisely. Able to recognize the tiniest deviation from factory specifications, the machines can now fit door panels, windshields and fenders more tightly”. In return this reduces panel gaps and decreases wind noise.

In the words of Ford engineer Thomas Burns, “the ability of the machines to register any difference in each vehicle on the line improves our quality by providing a custom-like build”.

Are you interested in developing game-changing technological advances? Ennomotive is looking for new solutions that can improve industrial operations for our partners: join us and take part in our innovation challenges!