SHARE

Reclaimed ThermoVoltaic: A disruptive Technology for Energy efficiency

Waste heat accounts for a painful 60% of the gasoline consumed by our cars, and in other Industrial applications the numbers are equally devastating.

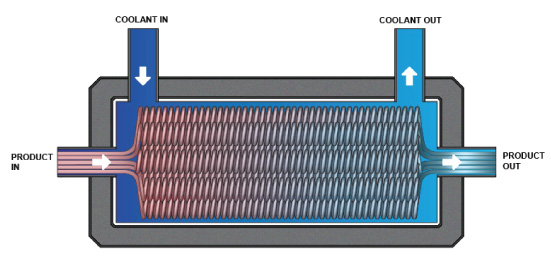

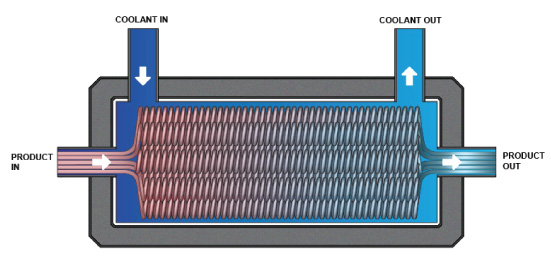

In chemical and refining Industry fluid flows are typically exchanged against each other to use the heat energy more efficiently (Example: Product with 200°C that has to be cooled down, against coolant with 60°C, that has to be heated up ). Those two (if their flows and heat coefficients are similar) would typically end up with temperatures (Product out: 150; Coolant Out:110°C) but to run efficiently high temperature differences (Engineering: Δt, speak "Delta-tee") are required.

Picture: Tube heat exchanger source bracton.com

At low Δt compared to ambient temperature, or if we lack another flow with compatible characteristics, there is just no other way than blowing it into the air, or cooling the flow down with cooling water- this Energy is lost. Especially with increasing Energy prices every kW lost does not only bother the pride of the Engineers, but it also has a dramatic effect on a factories bottom line. A regular industrial pipe with DN50 (diameter app. 50mm, similar to a normal sewage water pipe) with water running at a regular 3m/s (app. 10km/h or an advanced jogging speed) and with 40°C Δt of temperature loss, would add up to a loss of thermal energy of around 1000 kWh, per hour!

A new Technology promises to convert temperature differences of flows like those above mentioned to Electricity and therefore it would be able to recover a part of this Energy, even at a low Δt. Why is this a potential revolution? Because on a global level there are thousands of those small pipes in the Industry, draining energy 24/ 7 and those could be used to generate electricity. This energy then would not have to be produced with conventional power plants any more. The potential impact is enormous!

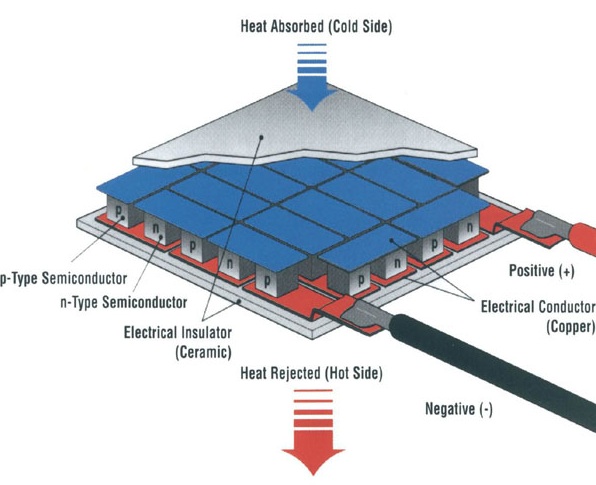

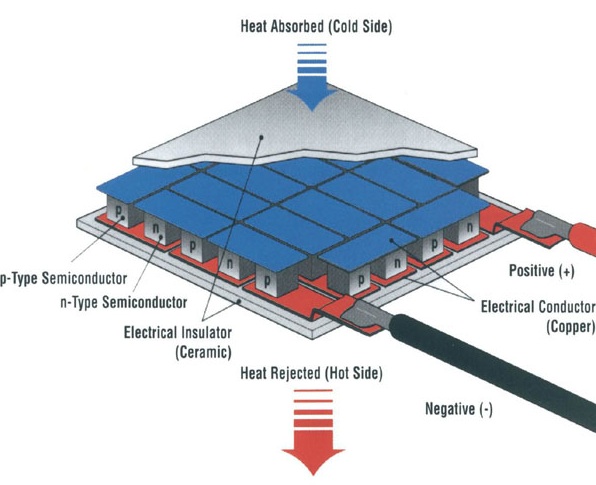

This new Technology is called Reclaimed ThermoVoltaic and the devices "Thermoelectric Generators" (TEG) work off the Seebeck principle to convert the flow of heat (from hot to cold) into electrical power with the use of thermoelectric semiconductors. A semiconductor is a material that is usually less electrically conductive than a metal and more electrically conductive than an insulator, such as glass. Semiconductors are also used to create devices such as transistors, LEDs, and solar panel photovoltaics (PV), and their electrical conductivity can be adjusted.

Picture: Tube heat exchanger source bracton.com

At low Δt compared to ambient temperature, or if we lack another flow with compatible characteristics, there is just no other way than blowing it into the air, or cooling the flow down with cooling water- this Energy is lost. Especially with increasing Energy prices every kW lost does not only bother the pride of the Engineers, but it also has a dramatic effect on a factories bottom line. A regular industrial pipe with DN50 (diameter app. 50mm, similar to a normal sewage water pipe) with water running at a regular 3m/s (app. 10km/h or an advanced jogging speed) and with 40°C Δt of temperature loss, would add up to a loss of thermal energy of around 1000 kWh, per hour!

A new Technology promises to convert temperature differences of flows like those above mentioned to Electricity and therefore it would be able to recover a part of this Energy, even at a low Δt. Why is this a potential revolution? Because on a global level there are thousands of those small pipes in the Industry, draining energy 24/ 7 and those could be used to generate electricity. This energy then would not have to be produced with conventional power plants any more. The potential impact is enormous!

This new Technology is called Reclaimed ThermoVoltaic and the devices "Thermoelectric Generators" (TEG) work off the Seebeck principle to convert the flow of heat (from hot to cold) into electrical power with the use of thermoelectric semiconductors. A semiconductor is a material that is usually less electrically conductive than a metal and more electrically conductive than an insulator, such as glass. Semiconductors are also used to create devices such as transistors, LEDs, and solar panel photovoltaics (PV), and their electrical conductivity can be adjusted.

Picture: A Thermoelectric Generator Source: topmagneticgenerator.com

First studies and pilot installations look very promising. But only time will tell whether installation costs are covered by the Energy saved, so that plants make sense both in an environmental as well as in a economic way, and whether this Technology will disrupt the industrial landscape.

We love energy recovery and innovative Technologies! If you work in this field and are interested in proving your skills, press the button below to participate in our latest challenge that addresses an applied case of energy recovery. If you have a story related to Energy recovery or Innovative Green Energy Technologies that you would like to share please drop us a mail.

Check out our energy challenge!

Picture: A Thermoelectric Generator Source: topmagneticgenerator.com

First studies and pilot installations look very promising. But only time will tell whether installation costs are covered by the Energy saved, so that plants make sense both in an environmental as well as in a economic way, and whether this Technology will disrupt the industrial landscape.

We love energy recovery and innovative Technologies! If you work in this field and are interested in proving your skills, press the button below to participate in our latest challenge that addresses an applied case of energy recovery. If you have a story related to Energy recovery or Innovative Green Energy Technologies that you would like to share please drop us a mail.

Check out our energy challenge!

Picture: Tube heat exchanger source bracton.com

At low Δt compared to ambient temperature, or if we lack another flow with compatible characteristics, there is just no other way than blowing it into the air, or cooling the flow down with cooling water- this Energy is lost. Especially with increasing Energy prices every kW lost does not only bother the pride of the Engineers, but it also has a dramatic effect on a factories bottom line. A regular industrial pipe with DN50 (diameter app. 50mm, similar to a normal sewage water pipe) with water running at a regular 3m/s (app. 10km/h or an advanced jogging speed) and with 40°C Δt of temperature loss, would add up to a loss of thermal energy of around 1000 kWh, per hour!

A new Technology promises to convert temperature differences of flows like those above mentioned to Electricity and therefore it would be able to recover a part of this Energy, even at a low Δt. Why is this a potential revolution? Because on a global level there are thousands of those small pipes in the Industry, draining energy 24/ 7 and those could be used to generate electricity. This energy then would not have to be produced with conventional power plants any more. The potential impact is enormous!

This new Technology is called Reclaimed ThermoVoltaic and the devices "Thermoelectric Generators" (TEG) work off the Seebeck principle to convert the flow of heat (from hot to cold) into electrical power with the use of thermoelectric semiconductors. A semiconductor is a material that is usually less electrically conductive than a metal and more electrically conductive than an insulator, such as glass. Semiconductors are also used to create devices such as transistors, LEDs, and solar panel photovoltaics (PV), and their electrical conductivity can be adjusted.

Picture: Tube heat exchanger source bracton.com

At low Δt compared to ambient temperature, or if we lack another flow with compatible characteristics, there is just no other way than blowing it into the air, or cooling the flow down with cooling water- this Energy is lost. Especially with increasing Energy prices every kW lost does not only bother the pride of the Engineers, but it also has a dramatic effect on a factories bottom line. A regular industrial pipe with DN50 (diameter app. 50mm, similar to a normal sewage water pipe) with water running at a regular 3m/s (app. 10km/h or an advanced jogging speed) and with 40°C Δt of temperature loss, would add up to a loss of thermal energy of around 1000 kWh, per hour!

A new Technology promises to convert temperature differences of flows like those above mentioned to Electricity and therefore it would be able to recover a part of this Energy, even at a low Δt. Why is this a potential revolution? Because on a global level there are thousands of those small pipes in the Industry, draining energy 24/ 7 and those could be used to generate electricity. This energy then would not have to be produced with conventional power plants any more. The potential impact is enormous!

This new Technology is called Reclaimed ThermoVoltaic and the devices "Thermoelectric Generators" (TEG) work off the Seebeck principle to convert the flow of heat (from hot to cold) into electrical power with the use of thermoelectric semiconductors. A semiconductor is a material that is usually less electrically conductive than a metal and more electrically conductive than an insulator, such as glass. Semiconductors are also used to create devices such as transistors, LEDs, and solar panel photovoltaics (PV), and their electrical conductivity can be adjusted.

Picture: A Thermoelectric Generator Source: topmagneticgenerator.com

First studies and pilot installations look very promising. But only time will tell whether installation costs are covered by the Energy saved, so that plants make sense both in an environmental as well as in a economic way, and whether this Technology will disrupt the industrial landscape.

We love energy recovery and innovative Technologies! If you work in this field and are interested in proving your skills, press the button below to participate in our latest challenge that addresses an applied case of energy recovery. If you have a story related to Energy recovery or Innovative Green Energy Technologies that you would like to share please drop us a mail.

Check out our energy challenge!

Picture: A Thermoelectric Generator Source: topmagneticgenerator.com

First studies and pilot installations look very promising. But only time will tell whether installation costs are covered by the Energy saved, so that plants make sense both in an environmental as well as in a economic way, and whether this Technology will disrupt the industrial landscape.

We love energy recovery and innovative Technologies! If you work in this field and are interested in proving your skills, press the button below to participate in our latest challenge that addresses an applied case of energy recovery. If you have a story related to Energy recovery or Innovative Green Energy Technologies that you would like to share please drop us a mail.

Check out our energy challenge!