SHARE

Mine Tailings Reprocessing Challenge (15K € in Prizes)

Mine tailings can be used to produce different kinds of glass but they need to be reprocessed to eliminate impurities. Can you come up with a cost-efficient way to turn this waste into valuable raw materials for the glass industry?

Join the challenge (click on the button below), register, and download the complete description of this competition.

The first deadline for submissions is 7th October.

Summary of the Challenge

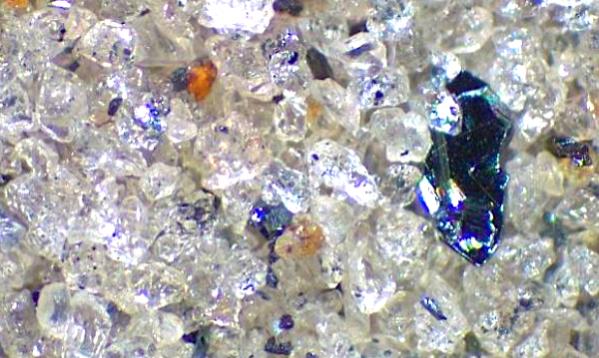

During mining operations, metallic ores and other inert materials are extracted from the ground and are usually stored in the surroundings of the mine. Those materials create a negative environmental impact and lose all their potential to be processed and produce valuable products. These waste materials (tailings) have different granulometry and are mainly composed of silica and smaller amounts of calcium oxide, magnesium oxide, aluminum oxide, and more. Silica can be used to produce different kinds of glass, such as flat glass products, bottles, or others that require different compositions and prices. However, the current materials found in tailings require a reprocessing to eliminate impurities at a reasonable cost.What the client is looking for

The main goal of this challenge is to find out the process and/or technology to turn this waste into valuable raw materials to be used in the manufacturing of different types of glass. To this end, it is necessary to develop a tailing-purification process that generates a new composition that roughly has the following characteristics:- the highest quality quartz glass (SiO2) as the final product (97%-99% purity)

- Fe and Cr oxides must remain below 0.1%.

- limit the maximum amount of other materials below 1%.

Evaluation Criteria

Participants submissions will be evaluated according to the following criteria:- Technical feasibility.

- The Best Business Case:

- First goal: Lowest initial investment (CAPEX)

- Second goal: Lowest operational cost (OPEX)

- The safest and lowest environmental impact