SHARE

Measure Energy accurately to manage Operations efficiently

Traditionally, metering has been used by utility companies to measure energy and bill for the quantity or volume of the utility being delivered and for a network to be balanced between the supplier and the shipper.

For some energy-intensive industries, energy cost is the highest and for many others, it is the second-highest cost after staff salaries. Therefore, measure energy for effective energy management is a big concern for saving money and resources at the same time. In order to save, you should know how much you consume. Metering plays a big role here.

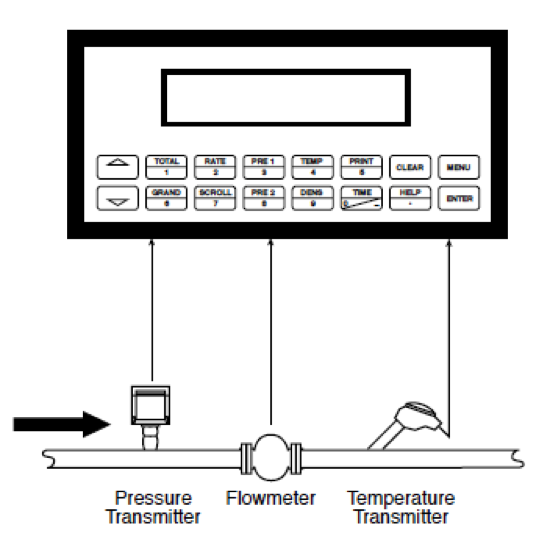

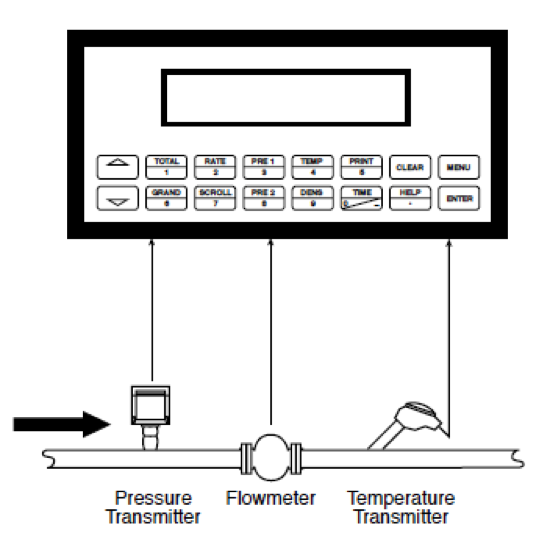

Industrial gases are normally measured in terms of equivalent volume units at stated reference conditions (temperature and pressure). To facilitate this, a gas metering system typically include a volumetric flow metering device, pressure and temperature sensors, and a computational device as shown in the figure below.

Source: http://www.kep.com/training-aids/ST2_training_aids/Gas_metering_intro.pdf

Volumetric flow measuring devices can be of different categories including:

Source: http://www.kep.com/training-aids/ST2_training_aids/Gas_metering_intro.pdf

Volumetric flow measuring devices can be of different categories including:

Source: http://www.foodprocessing.com.au/content/training-education/news/ams-to-distribute-katronic-rsquo-s-range-of-ultrasonic-flowmeters-475873428

Another similar example is the monitoring of the speed of ground vehicles from distance. The method based on a specialized radar that uses the Doppler Effect to produce velocity data about the object. Some systems are equipped with photographic or video facilities to record speed violations.

Source: http://www.foodprocessing.com.au/content/training-education/news/ams-to-distribute-katronic-rsquo-s-range-of-ultrasonic-flowmeters-475873428

Another similar example is the monitoring of the speed of ground vehicles from distance. The method based on a specialized radar that uses the Doppler Effect to produce velocity data about the object. Some systems are equipped with photographic or video facilities to record speed violations.

Source: https://en.wikipedia.org/wiki/Speed_limits_in_Denmark

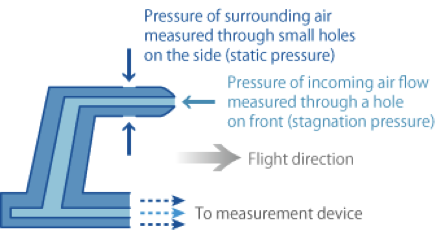

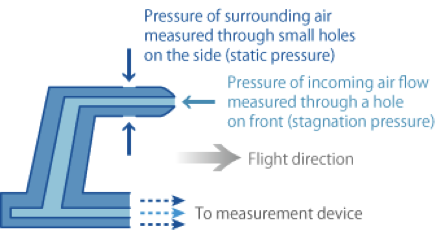

The speed of an aircraft is measured by using a Pitot tube. It calculates the airspeed from dynamic pressure which is the difference between static pressure and stagnation pressure as shown in the figure below.

Source: https://en.wikipedia.org/wiki/Speed_limits_in_Denmark

The speed of an aircraft is measured by using a Pitot tube. It calculates the airspeed from dynamic pressure which is the difference between static pressure and stagnation pressure as shown in the figure below.

Source: http://world.honda.com/HondaJet/know/02/

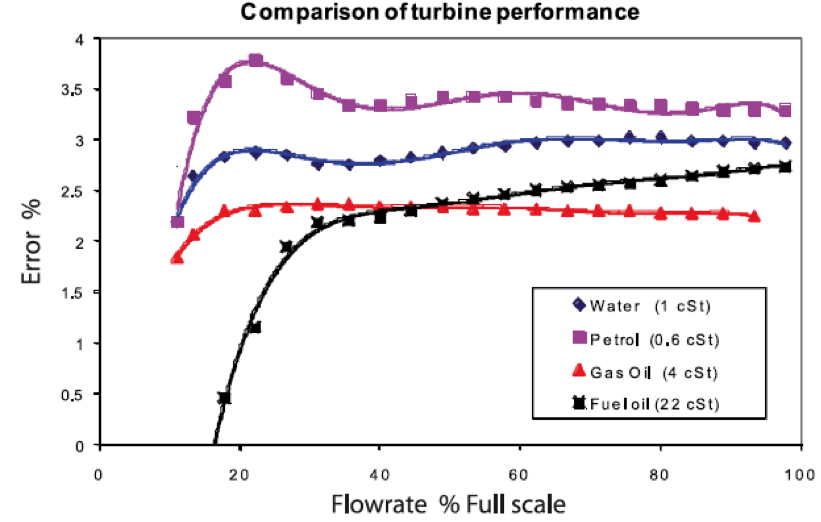

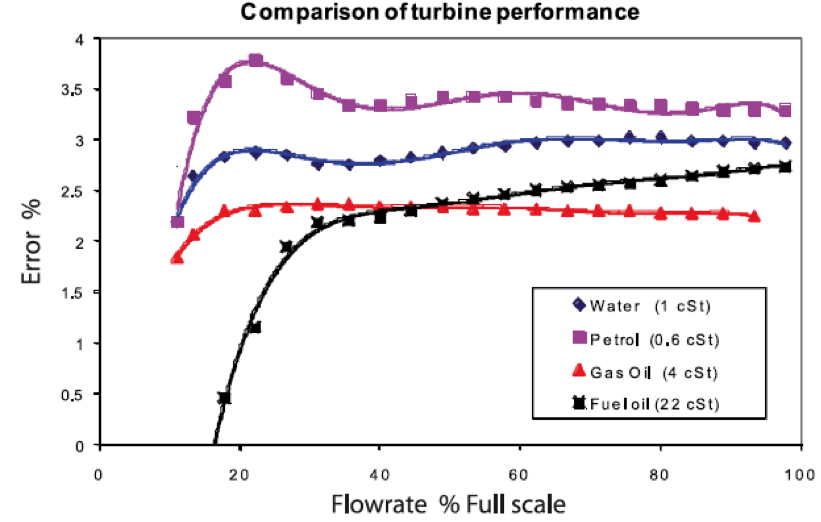

As the costs of fuels and consumables continue to rise, the ability to accurately measure the real usage is a must to control your operations costs. However, the use of the same flow meter for different fluids or deviations from the standard scale of measurement in which the meter is designed can lead to higher errors as shown in the figure below for a turbine flow meter. The calibration of flow meters for each different measurement campaign is crucial for getting more reliable reading.

Source: http://world.honda.com/HondaJet/know/02/

As the costs of fuels and consumables continue to rise, the ability to accurately measure the real usage is a must to control your operations costs. However, the use of the same flow meter for different fluids or deviations from the standard scale of measurement in which the meter is designed can lead to higher errors as shown in the figure below for a turbine flow meter. The calibration of flow meters for each different measurement campaign is crucial for getting more reliable reading.

Source: http://www.watergroup.com.au/gas

The consumer benefits of smart metering include getting more insight into usage patterns gives more understanding to determine and reveal potential areas and opportunities for resource and cost savings across the facility.

Are you an engineer? What was your best project that helped a company measure energy more efficiently? Would you like to connect and help other companies solve their open innovation energy challenges?

Challenge yourself and learn continuously!

Source: http://www.watergroup.com.au/gas

The consumer benefits of smart metering include getting more insight into usage patterns gives more understanding to determine and reveal potential areas and opportunities for resource and cost savings across the facility.

Are you an engineer? What was your best project that helped a company measure energy more efficiently? Would you like to connect and help other companies solve their open innovation energy challenges?

Challenge yourself and learn continuously!

Source: http://www.kep.com/training-aids/ST2_training_aids/Gas_metering_intro.pdf

Volumetric flow measuring devices can be of different categories including:

Source: http://www.kep.com/training-aids/ST2_training_aids/Gas_metering_intro.pdf

Volumetric flow measuring devices can be of different categories including:

- Positive displacement

- Ultrasonic and

- Differential pressure meters (eg. orifice or Pitot tube)

Source: http://www.foodprocessing.com.au/content/training-education/news/ams-to-distribute-katronic-rsquo-s-range-of-ultrasonic-flowmeters-475873428

Another similar example is the monitoring of the speed of ground vehicles from distance. The method based on a specialized radar that uses the Doppler Effect to produce velocity data about the object. Some systems are equipped with photographic or video facilities to record speed violations.

Source: http://www.foodprocessing.com.au/content/training-education/news/ams-to-distribute-katronic-rsquo-s-range-of-ultrasonic-flowmeters-475873428

Another similar example is the monitoring of the speed of ground vehicles from distance. The method based on a specialized radar that uses the Doppler Effect to produce velocity data about the object. Some systems are equipped with photographic or video facilities to record speed violations.

Source: https://en.wikipedia.org/wiki/Speed_limits_in_Denmark

The speed of an aircraft is measured by using a Pitot tube. It calculates the airspeed from dynamic pressure which is the difference between static pressure and stagnation pressure as shown in the figure below.

Source: https://en.wikipedia.org/wiki/Speed_limits_in_Denmark

The speed of an aircraft is measured by using a Pitot tube. It calculates the airspeed from dynamic pressure which is the difference between static pressure and stagnation pressure as shown in the figure below.

Source: http://world.honda.com/HondaJet/know/02/

As the costs of fuels and consumables continue to rise, the ability to accurately measure the real usage is a must to control your operations costs. However, the use of the same flow meter for different fluids or deviations from the standard scale of measurement in which the meter is designed can lead to higher errors as shown in the figure below for a turbine flow meter. The calibration of flow meters for each different measurement campaign is crucial for getting more reliable reading.

Source: http://world.honda.com/HondaJet/know/02/

As the costs of fuels and consumables continue to rise, the ability to accurately measure the real usage is a must to control your operations costs. However, the use of the same flow meter for different fluids or deviations from the standard scale of measurement in which the meter is designed can lead to higher errors as shown in the figure below for a turbine flow meter. The calibration of flow meters for each different measurement campaign is crucial for getting more reliable reading.

Source: http://www.tuvnel.com/_x90lbm/The_Calibration_of_Flow_Meters.pdf

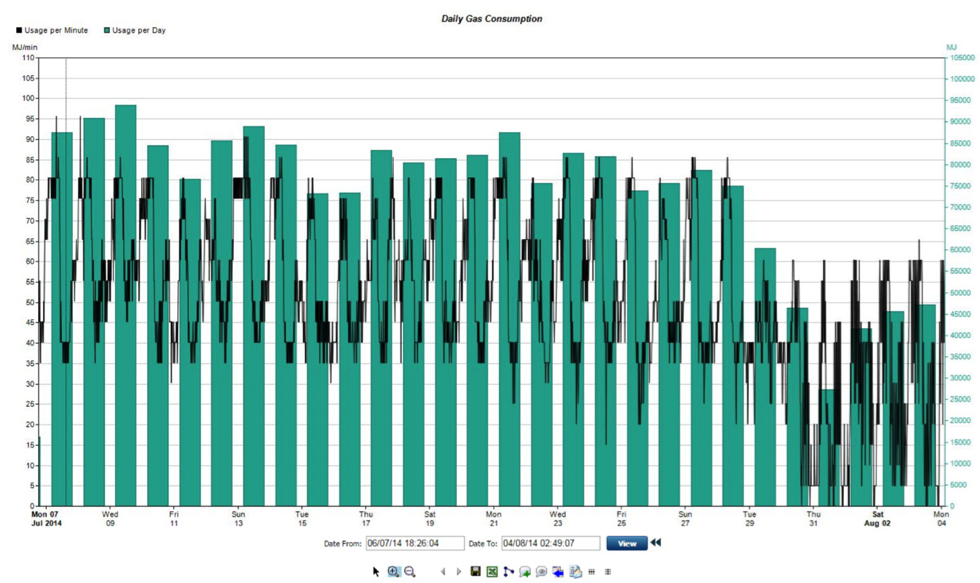

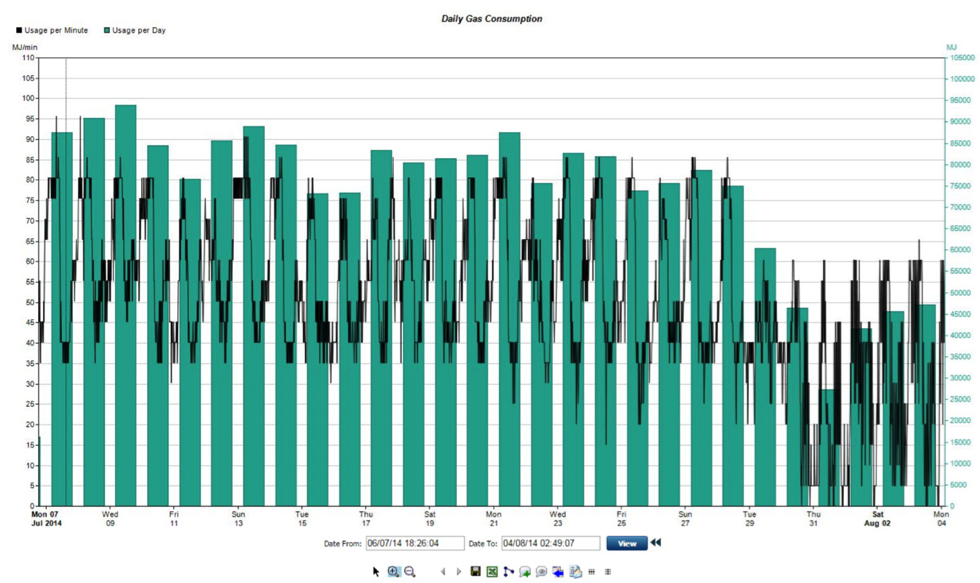

The meter reading was traditionally collected manually. Nowadays, in many installations, Automatic Meter Reading (AMR) is possible and helps also reducing the metering reading cost. Smart metering is a novel concept that enables real-time consumption data collection and billing accordingly. The following figure shows one example of a daily gas consumption pattern collected by a smart gas meter. Source: http://www.watergroup.com.au/gas

The consumer benefits of smart metering include getting more insight into usage patterns gives more understanding to determine and reveal potential areas and opportunities for resource and cost savings across the facility.

Are you an engineer? What was your best project that helped a company measure energy more efficiently? Would you like to connect and help other companies solve their open innovation energy challenges?

Challenge yourself and learn continuously!

Source: http://www.watergroup.com.au/gas

The consumer benefits of smart metering include getting more insight into usage patterns gives more understanding to determine and reveal potential areas and opportunities for resource and cost savings across the facility.

Are you an engineer? What was your best project that helped a company measure energy more efficiently? Would you like to connect and help other companies solve their open innovation energy challenges?

Challenge yourself and learn continuously!