SHARE

Car Crash Challenge: How to absorb the mechanical energy 🚘

Car Crash and Mechanical Energy Absorption

Approximately 1.35 million people are killed in car crash each year. That means, on average, fatal crashes cause approximately 3,700 deaths per day. An additional 20-50 million people are injured or disabled. Fatal car crashes rank as the 8th leading cause of death and account for 2.2% of all deaths globally (CDC). In this article we understand one of the engineering challenges the automotive industry is facing, as well as what happens when two vehicles collide at high speed, and how these vehicles absorb the mechanical energy of the crash.

Written by Manuel Francisco Ortuño Sánchez, award-winner of the open innovation program ANTOLIN iJUMP

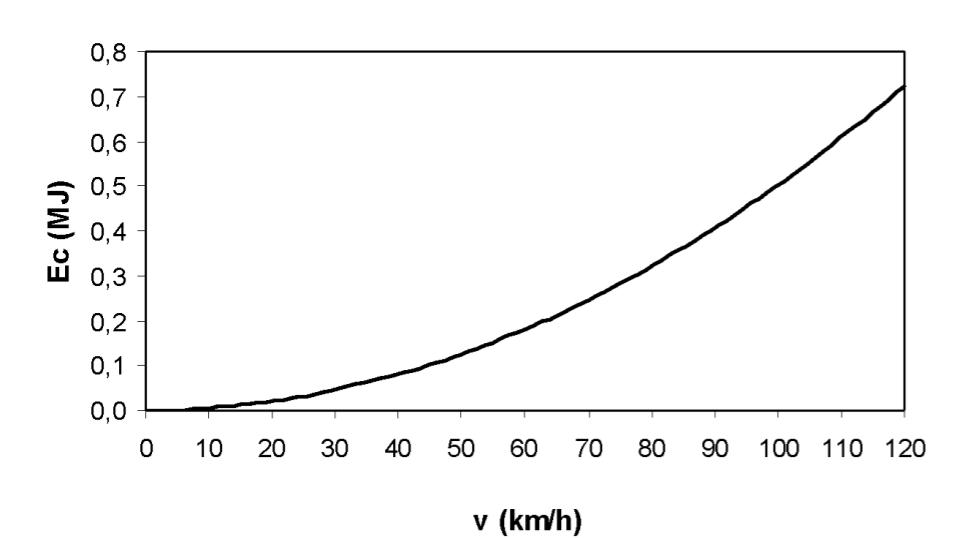

A car's kinetic energy increases according to the equation Ec=1/2 m v2, so the energy is still significant regarless of the speed.

In some countries, the maximum speed allowed on highways for a 1300 kg passenger car is 120 km/h, and so the kinetic energy will be over 0,7 MJ (See Figure). This energy is equivalent to a car falling from a 50 meters high-rise building. In case of an impact, the kinetic energy turns into destructive mechanical energy. When a traffic collision happens, and one vehicle crashes into another, or into an object, its structure is subject to a violent deceleration, which is passed on to the passengers. Current vehicles are designed to protect passengers by preparing the structure to controllably fold over in case of a collision. The cabin will remain relatively rigid, ensuring its integrity and directing the loads toward other car parts.

When a traffic collision happens, and one vehicle crashes into another, or into an object, its structure is subject to a violent deceleration, which is passed on to the passengers. Current vehicles are designed to protect passengers by preparing the structure to controllably fold over in case of a collision. The cabin will remain relatively rigid, ensuring its integrity and directing the loads toward other car parts.

During the impact, the mechanical energy is "used" to

- deform

- fold

- compress

- break the vehicle materials through the controlled fold over zones, designed by the manufacturer.

This way, passengers experience less deceleration and the safety compartment enclosing them is subject to fewer loads, which reduces the impact consequences. Otherwise, the full energy will pass on the passengers.

Car Crash: One of the Challenges in the Automotive Industry

Unfortunately, the current structure of passenger cars cannot absorb all the mechanical energy generated in a high-speed crash. In fact, crash tests like the ones performed by the Europen program EuroNCAP use a maxium speed of 64 km/h on a frontal collision and considers that, the surface the vehicle crashes into is also foldable and partially absorbs the energy.

In the past, the crash test considered 56 km/h as the maximum speed but now it is becoming more restrictive to come closer to a real situation. A high-speed crash between two passenger cars, or a lower-speed crash between a passenger car and a truck or a rigid object (a big tree or a concrete wall) is, initially, inelastic (the car absorbs the mechanical energy) but immediately turns elastic (the car bounces back when it cannot absorb more energy).

Vehicles are increasingly lighter (less mass) mainly because manufacturers, consumers and regulatory bodies seek a reduction in fuel consumption and pollution. This also improves the characteristics of the vehicle and reduces the kinetic energy if driving at the same maximum speed.

However, even though modern vehicles accelerate very easily and reach a high speed in no time, an increasing number of vehicle parts are being replaced by plastics or low-density composites. Consequently, the structure is not able to transform as much mechanical energy from the crash into energy that deforms, folds and compresses the materials.

To contextualize, the Young's modulus of steel is around 200 GPa, while aluminum alloys is a third, and magnesium half the aluminum's. Plastics and composite materials have a Young's modulus of a tenth the steel's. Therefore, structures made out of these materials have a lower absorption capacity.

Vehicle Compatibility in case of a Car Crash

Another aspect to consider is the compatibility between vehicles in case of a car crash. A bus full of passengers driving at 90 km/h may have a kinetic energy of 3 MJ (4 times higher than a car). Also, its bottom part, where the chassis, the engine and the wheels are, has higher number of higher-density materials (i.e. steel). In case of a collision between a bus and a car, most of the energy would go towards the car.

For electric vehicles, a significant part of the car's mass is not the structure but the batteries. Batteries are made with low Young's module materials, which means that they cannot absorb much mechanical energy. Even if they were made with different materials, their geometry and placement withing the vehicle are not suitable for car crashes.

Another case are military vehicles, with a higher mass than civil ones due to their heavy shielding. The structure of these vehicles is very rigid, which means their energy absorption capacity is very limited in case of a collision and the compatibility with a lighter vehicle is not very good.

To improve the mechanical energy absorption in vehicles for all the above-mentioned cases, new passive security devices should be incorporated. These devices would be placed in strategic spots like, for example, as internal bumper or in the passengers compartment, doors, etc. It would improve compatibility between light and heavy vehicles significantly in case of collision.

Regarding electric cars, it would increase the energy absorption capacity of the structure and their behavior in case of collision. A complementary approach would be to improve the crossbar structure of the car's chassis by increasing the energy absorption capacity in case of collision.

Tell us how else you would solve the car crash challenge and explore what ennomotive has to offer or just join the ennomotive community to discuss about this and other engineering topics.

About the author

Grupo Antolin, together with ennomotive, launched 3 challenges in May 2019 as part of the 1st wave of its open innovation program ANTOLIN iJUMP which came to a completion 73 solutions, five of which have been awarded: Petar Smiljanic, from Serbia, Can Akgün, from Turkey, Manuel Ortuño, from Spain, David Barron, from United States, and Cillian Hickey, from the UK.