SHARE

Liquid Harvest: Creating a Circular Economy via the UNIVAT SYSTEM

Tim Straatmans, an Australian engineer and inventor/manager at CFS-UNIVAT and Carbon Footprint Solutions, wrote an article about liquid harvest and how to treat and repurpose waste from tailing dams. Of all the water on Earth, only 3% of it is freshwater, 1% is ice-capped snows, 1/2 % is underground in aquifers almost unattainable, 1% is now tainted by human interventions, and 1 or 2 % is left for us to use (and most of that is in the industry for the process). Waste streams generated from all industries are considered by-products and offtakes that are not in the interests of that particular industry. Invariably, most of these by-products are from a water cleaning process, or indeed a washing, a watering down, a series of water flow separation, or indeed using water as a neutralizer to annul chemical harshness. In almost all cases there are ponds, dams, or holds of these liquidized waste streams stored forever, in ever-increasing sizes, to accommodate an ever-increasing production. These are commonly referred to as “Tailings”. So, throughout the world over countless years, industries of thousands of varying types have stored these tailings without proper consideration to what has now become an obvious trilogy of scenario: By and large, the bigger industries do not have any liquid harvest system to cater for the sheer volume of tailings generated on an hourly or daily basis, so the ongoing management of a pond/tailing dam methodology has been widely accepted as the world’s best practice. There is an estimated 3 trillion tonnes of liquidized waste just in Red Muds processing derived from Iron Ore extraction from ores, and Alumina processing from bauxites, let alone the plethora of other industrial ponds thereabouts. Many of these long-standing (and still developing) dams are now seeing wall collapses creating massive environmental and human tolls, unacceptable to mainstream society. The existing well-practiced liquid harvest methodologies do involve many processes, in unison or complimentary in series. These invariably will include all the following;

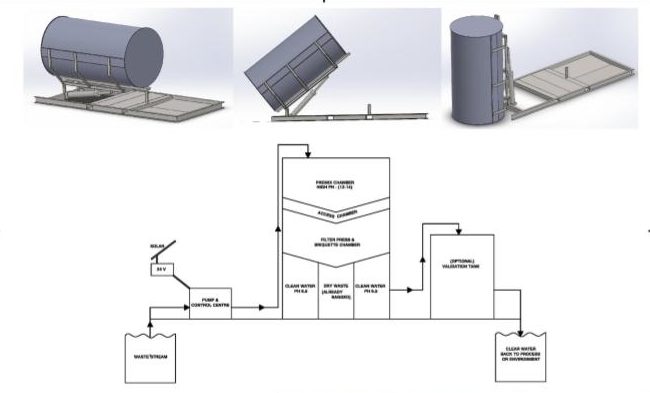

In consideration of all the above-mentioned situations, the CFS Group has invented a UNIVAT SYSTEM which comprises three main portions, suitable for almost any liquidized waste stream. So, in one process, it is possible to eliminate all the interfacing issues aforementioned, by adding a 100% natural agent and designing a tailor-made system to suit each varying waste stream. It is also possible to ascertain clean water (almost no TDS, almost no Chemical Oxygen Demand -CoD’s-, almost no Biological Oxygen Demand -BoD’s) and extract and bind the waste items into a powder or dry briquette in minutes. Then the system makes sensible considerations of the dry wastes, as to constituency, varying methods to extract, and indeed value-adding options. The resulting water, now clean (and with a few added protocols), can be made potable. However, in its current form, this water is most certainly fit for animals, re-entry into the environment, or simply back into the plant for re-use.  Due to the various waste streams generated, it is mandatory to take some factors (the number of dissolved solids, the acidity, heavy metals, the water/waste ratio, and so forth) into consideration. For most tested waste streams, the agent/waste ratio was approximately 1:3000. To clarify, that is 1 kilogram of dried agent per 3,000 liters of liquidized waste. Also, note this is the average, it depends on the above-mentioned variables and may change. The cost is circa $12.00 (AUD) per kilo but, of course, in bulk (container purchases) reduces that effectively. There is an overall 25% reduction in operations by using this system as opposed to mainstream plants. Under laboratory tests, the full-sized unit is yet to be completed to enhance that ability. The speed at which this system separates waste and water uses less power, fewer interactions with other parts or downstream plants, and less energy to process by utilizing gravity for transfers, bagging encompassed (or direct connection to conveyors on a full scale). Redundancy is overcome by way of several machines, so whilst one is under a filter change, the other/s continue the cycle. ( Model CFSU-07 stands 3.7 M high and 2.0 Metre diameter, but is laid to its side and split longitudinally for ease, safety, access, and efficiency). Secondly, the model depicted above, CFSU-07, caters to approx. 20 cuM per hour of liquidized waste at 20% TDS under 315 power. 24 Volt powered stand-alone remote units have been designed for islands, communities. SCADA controls, satellite monitoring, remote adjustments, and reporting are all within the designs, dependent upon the client’s requirements. These photos depict the separation in less than a minute with clear water now presented along with a coagulated and completely hydrophobic gathered waste. [gallery columns="2" size="medium" ids="21896,21900"] [gallery columns="2" size="medium" ids="21894,21902"] If you want to read more about the liquid harvest, tailings, waste management, and circular economy, check out ennomotive's blog and discover what ennomotive can do for you. Join the engineering community

Due to the various waste streams generated, it is mandatory to take some factors (the number of dissolved solids, the acidity, heavy metals, the water/waste ratio, and so forth) into consideration. For most tested waste streams, the agent/waste ratio was approximately 1:3000. To clarify, that is 1 kilogram of dried agent per 3,000 liters of liquidized waste. Also, note this is the average, it depends on the above-mentioned variables and may change. The cost is circa $12.00 (AUD) per kilo but, of course, in bulk (container purchases) reduces that effectively. There is an overall 25% reduction in operations by using this system as opposed to mainstream plants. Under laboratory tests, the full-sized unit is yet to be completed to enhance that ability. The speed at which this system separates waste and water uses less power, fewer interactions with other parts or downstream plants, and less energy to process by utilizing gravity for transfers, bagging encompassed (or direct connection to conveyors on a full scale). Redundancy is overcome by way of several machines, so whilst one is under a filter change, the other/s continue the cycle. ( Model CFSU-07 stands 3.7 M high and 2.0 Metre diameter, but is laid to its side and split longitudinally for ease, safety, access, and efficiency). Secondly, the model depicted above, CFSU-07, caters to approx. 20 cuM per hour of liquidized waste at 20% TDS under 315 power. 24 Volt powered stand-alone remote units have been designed for islands, communities. SCADA controls, satellite monitoring, remote adjustments, and reporting are all within the designs, dependent upon the client’s requirements. These photos depict the separation in less than a minute with clear water now presented along with a coagulated and completely hydrophobic gathered waste. [gallery columns="2" size="medium" ids="21896,21900"] [gallery columns="2" size="medium" ids="21894,21902"] If you want to read more about the liquid harvest, tailings, waste management, and circular economy, check out ennomotive's blog and discover what ennomotive can do for you. Join the engineering community

Liquid Harvest: The need to Treat Waste Streams

- Water quality,

- Waste storage,

- Environmental impacts.

Remedies

Liquid Harvest: Existing Solutions

- The holding pond, dam, or facility.

- Pumps or a gathering station.

- Holding and settling tanks.

- Large-particle separators.

- Flocking process.

- Sometimes a neutralizer process.

- Clarifiers (sorting the separation of the fine).

- Centrifuges.

- Filter presses.

- Value-added processes.

The UNIVAT SYSTEM

- The Univat Machine

- The 100% natural Agent blend

- A protocol that is unique to each stream.

Points of Difference of the UNIVAT System compared to other treatment plants

- 100% Natural – No chemicals.

- Scalable models (from backpacker through to Industrial applications).

- Portable models for intermittent cleaning in regions.

- Stand-alone (24V, solar/wind) powered for remote regions or full-mains power (options).

- SCADA and satellite for control monitoring worldwide and maintenance assistance.

- Far less moving parts (Univat replaces 5 machines in a container).

- Cost competitive advantages and in many cases, an only option.

- Rent/ hire/ buy options.

- Scalable Business Plan.

- Unique design, unique agent, and protocols.

- Win-win for a client, owner, and operator.

- Huge appeal to Humanitarian causes worldwide

- Appeases environmental issues for Governments, Municipalities, NGO’s, Mining Sectors

- The Value-Adding of varying waste streams becomes generated stand-alone businesses

Savings

- Holding dams can be eventually reclaimed back to useful land.

- Water for process costs reduced.

- Environmental costs, fees, and levees adjusted favorably or stopped.

- Value-adding industries for re-purposing.